Common Problems with Standard Hot Air and Boiler Steam For Packaging Sector Products

…now overcome by OAB® Hybrids

Some hot-air, vacuum-assisted, and high-pressure boiler steam disadvantages are discussed below. We recommend OAB® steam. Rapid labeling has never been more accessible, even for filling bottles with unusual curvature. Possibilities of 90% savings in energy and water even with complex bottles. possibilities of high disinfection. Possibilities of improved cotton fibers. Use pure, high-quality steam.

Hot-Air Systems: Possible Disadvantages

- High distortion could lead to melting/burns, a slower overall process, or lower quality.

- Sometimes a reduced shininess of labels is noted in scattering experiments (MHI can do a laser scattering experiment for you to establish shininess for your brand); please contact MHI.

- Higher energy cost and larger footprint.

- Request Information

Boiler Steam: Possible Disadvantages

- Stickiness

- Residual water inside the labels

- Very high energy use with traditional pressure boilers. Many steps vacuum then pressure. Leads to fatigue and constant certification issues.

- High installation price and often a need for continued certifications.

The OAB® Steam Generator is now Available for such applications. The OAB® steam comes with a low capital cost structure and high-quality labels.

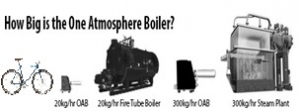

- High energy efficiency savings are 50- 95% over traditional high-pressure boiler steam. For example, changing from an 80 kW * BHP) boiler to a (4-12) kW OAB® Steam Generator yields savings of US $60,000 – $65,000 per year @ $0.10/kWh, assuming continuous operations.

- The cost of changing over could be as small as $1000 per month for a typical 4-year period of purchase amortization. The return on investment is high (please contact MHI for ROI calculations).

- One additional benefit is mixing and matching bottle sizes without needing to change any set-up—no need to be restricted to one belt line either.

- Steam piping from boilers can be long and thus lower the efficiency of traditional steam systems. OAB®equipment can be located directly by the label shrinkage machine.

- Contact MHI for easy design steps and shrinkage vs. speed. Installs within a few hours. No certifications. Relocate as desired.

- Enjoy MHI Financing.

Please request MHI for your ROI calculations and affordable monthly payments, or calculate your savings with high energy efficiency.*

Steam Generator Models, Plasma Steam Models, and Steam Chambers

* Small Print and Disclaimer:

This return on Investment (ROI) analysis is very approximate. Savings and benefits to users could be more or less than presented above. The calculations shown indicate and will vary for specific applications, equipment, and use conditions. This is an approximate guide, and the template should be modified for the customer’s specific use. The interest rates, energy, equipment, and other costs used in the analysis are subject to change at all times. MHI does not guarantee or warrant any specific ROI analysis that a purchaser may use in their decision-making process. The responsibility for an accurate financial assessment and ROI rests with the customer. Please visit the benefits page for typical calculations.

Learn more about OAB® and its applications.

How do Temperature and Pressure Impact a Steam Reaction?

OAB® Compared to Traditional Boilers

Steam Calculator, Productivity Enhancement and FAQs |Physical Properties of Moist Air/Gas | What are Steam and Humidity?

Productivity Enhancement and FAQs

Physical Properties of Moist Air/Gas

High-Efficiency Steam Recirculating Ovens

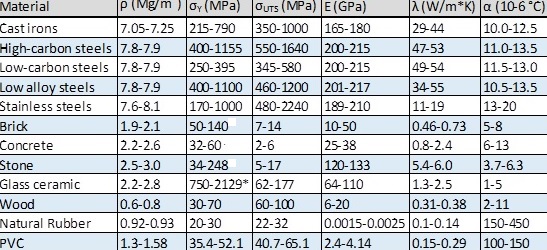

Properties of Solid Materials. Density, Yield or Comprehensive Strength, Ultimate Tensile Strength, Elastic Modulus,

Thermal Conductivity and Thermal Expansion

Natural Colors. Make it true with clean steam.

Want to find out how MHI can help you meet your steam needs? Fill out a quick questioner and we will help find a solution to meet your needs.