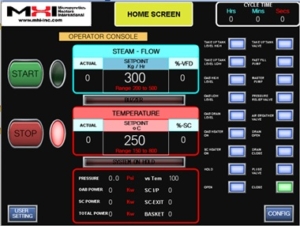

Electronic Controllers, Electric Power, and Temperature Control Panels with Excellent Communication Capabilities.

Enhanced Easy-Read Instrument Cluster Configuration for Temperature, Performance Efficiency, and Process Metrics.

Not all control panels are identical. When evaluating electric control panels, it’s crucial to assess factors such as connector type, craftsmanship quality, and instrument performance, including the SCR’s ability to operate in phase-angle mode or switch to zero-cross control. Additionally, it is vital to consider the contactor or disconnect quality, the brand of the instruments (including the types of variables they can support and display, as well as whether they enable external control, including an external E-Stop), and ensure that the panels and their components meet safety standards such as UL508A or CE certification, when required and so ordered by the customer. MHI control panels support Modbus TCP/IP and other communication protocols via proprietary software to improve customer process performance. MHI also provides HMI displays and straightforward programming on several electric control panels.

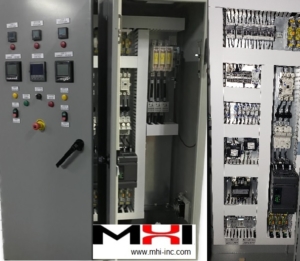

Three Phase |Multi Zone TRIPAN | TRIPAN-PLUS with Easy to use HMI displays with PLC controls.

Easy off-site operations

Compact UL508A Electric Control Panels

Electric Control Panels are on a Stand

Mega Watt Industrial Electrical Heating Systems

TRIPAN PLUS

NEMA-4

MW Panels

Use with all Electrical Heater Devices for Accurate Control for 380V, 400V, 415V, 440V, 480V, 600V,690V

BPAN-UL

BPAN-O-PLUS (front), BPAN-O-PLUS backface pictures (with COMM options). Typical only. Please refer to specific quote numbers for a precise call-out of the features.

Cleanly Engineered Electric Temperature and Power Panel Layout

Multi-Zone – 3 Phase. Control panels (TRIPAN and TRIPAN-PLUS MODELS)

Please note that there will be some differences between the Panels offered for different devices. This is required for optimizations or meeting price points. Please refer to your specific requirements in a quote for the exact features and instruments included.

Three-Phase Control Panel Options

The three-phase control panels offered by MHI are of two kinds. The ITRIPAN is for steady loads, and the TRIPAN – is when more complex control is required for a process.

A significant difference between the two kinds of panels lies in the functionality of the SCR in the panels. The SCRs used in the TRIPANs offer softer load control and significantly more sophisticated control options with current limit stabilization.

ITRIPAN

- One control zone

- One limit controller

- Quality controller

- Contactor for the load.

- Fuses

- Indicator for heater-on

- Junctions for thermocouples

- NEMA – 4 or NEMA 12. Box cooling 3R Style

- SCR -2 pole, zero-crossover type with proportional functions.

OAB steam generator software control

TRIPAN andTRIPA-PLUS

- One to multiple control zones. The TRIPAN-PLUS has PLC and touchscreen HMI controls.

- As required, limit controllers (Typically Eurotherm or similar)

- Quality process controller (Typically, the brands offered are Eurotherm or similar. cUL, CSA, UL CE Rated)

- The contactor (s) for the load

- Fuses

- Indicators for heater-on and other indicators

- Junctions for thermocouples

- NEMA – 4 or NEMA 12. Box cooling 3R Style or AC cooling

- SCR -Phase angle fired with current limit

- Ethernet as required or RS485 (customer option for communication).

- Optional PLCs depending on the type of device

- Optional HMI depending on control options and type of device

- EStop and remote Estop connection

- Other dry contacts for customer integration into systems like Bacnet

BPAN-O and BPAN-O-PLUS Control Panels

Over-temperature read-out and related control provided with PLUS models only. UL Rated displays. cUL and UL panels on request.

Please note that there will be some differences between the Panels offered for different devices. This is required for optimizations or meeting price points. Please refer to your specific quote for features.

BPAN-O models have a UL microprocessor (PID) programmable controller

BPAN-O models have a UL microprocessor (PID) programmable controller- Best soft start and current limit included

- Over-temperature controller available in BPAN-O-PLUSDurable enclosure for Models (weight is approx. 14 kg for models).

- Optional: As quoted, digital communications RS232/485 120V and 220V/ models.

- 220V Bpan models up to 6-8 KW. The 120V models are up to 1.5KW.

- Fan or power controller in some models

- SCR power controller with current limiter (extended soft start), please call for details

- Sold separately or with small furnaces and Thermoplate™ or Airtorch®

- Plug-and-play Data Acquisition System (optional) – MHI DACS

- Remote on/off (optional)

BPAN-O-120T, BPAN-O-120NT and BPAN-O-240

The corresponding PLUS models will have over-temperature controls.

BPAN Dimension: 8 1/2” (H) x 12 ¼”(D) x 19 7/8”(W) (Includes Conduit Connector Extender in the depth

Clean and compact layout as per UL standards. Dimension. Please note that the dimensions will differ for specific panel ratings for cUL and other standards.

(Over-temperature controller included in all BPAN-O-PLUS models)

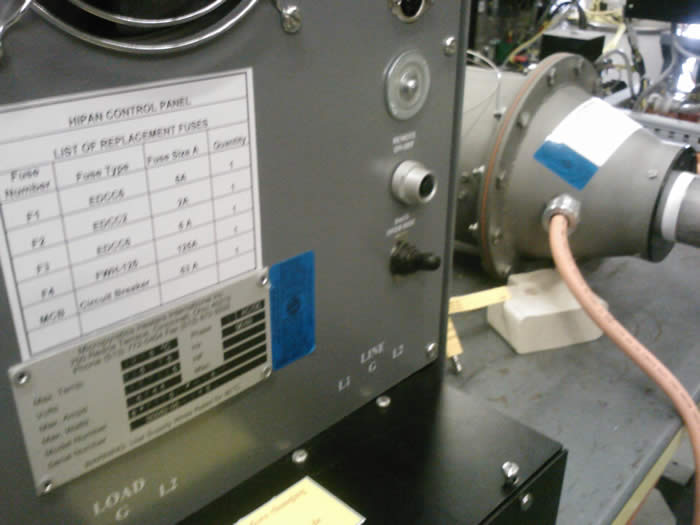

HIPAN & XPAN Control Panels

Please note that there will be some differences between the Panels offered for different devices. This is required for optimizations or meeting price points. Please refer to your specific quote for features.

Stands.

Process or programmable temperature controller

Over-temperature controller

Ammeter

SCR power controller with current limiter (extended soft start)

Durable enclosure

Thermocouple optional with every box (specify type & length)

Optional digital communications are offered as options.

HIPAN: 208V/220V/240V up to 55 amps

XPAN: 208V/220V/240V up to 75 amps

Plug-and-play Data Acquisition System – MHI DACS (optional)

Size: | HIPAN – 18″ H x 18″ D x 10″ W XPAN – 19″ H x 29″ D x 11″ W |

Weight: | HIPAN – 22 Kg (approx) XPAN – 34 Kg (approx) |

POWERPHASE SCR’S

Please note that there will be some differences between the Panels offered for different devices. This is required for optimizations or meeting price points. Please refer to your specific quote for features.

Why is an SCR required? An SCR helps improve the efficiency and life of heaters by allowing users to match the power required to the application’s requirements.

Why is a VFD required? A variable frequency drive (VFD) can help improve the efficiency of electric motors in industrial applications, such as blowers, by allowing users to match the blower speed to the application’s requirements

A complete range of SCR SINGLE and THREE PHASE power controllers are available from MHI. SCRs for MHI Panels only.

When requesting a quote, please confirm the Model Number and Serial Number of the Panel.

Features:

- Advanced hybrid design incorporating logic & analog circuits

- Compact, bulkhead mounting for easy installation

- The isolated heat sink, shrouded electronics meeting CE norms for added safety

- Phase angle control

- Field adjustable current limit

- Field adjustable soft start

- Semiconductor fuse, MOV, Snubber circuit protections

- User configurable inputs

- Standard models and customization ( factory configured for your application )

- Hundreds of installations

- Comprehensive operating, installation, and troubleshooting manual

- Unbeatable price and delivery

- One-year warranty.

Multi-zone process controllers are custom made for complex/continuous heating solutions. Calculate 3 Phase Power.

Versatile furnace and heater control panel

Control Panel Mix

![]()

Multiple Zone Control Process or Programmable Temperature Controller.

ITRIPAN, TRIPAN & RPAN3 – 3 Phase Control Panels

Over-temperature Controller

3 Phase Voltage & Current read out on all phases with selector switch

Optional digital communications options. Ethernet TCP/IP.

Durable enclosures

Continuous duty cycle

3 phase 208/240/480/600 KVA please specify

For custom control panels, Contact MHI for additional details.

MHI-DACS – Data Acquisition Control Software (optional)

XPAN GHGA XPAN 2

VPAN Control System.

Controls for Laboratory Furnaces, Airtorch™, Coils and Thermoplates

Contact MHI for DC Control Panels

Size and weight-optimized for the greatest flexibility. Can be remotely located. Easy to connect. Easy to use.

Airtorch(R) controllers offer infinite analog, FANCS, or programmable temperature capabilities.

FAQ: People often ask how much energy does the control panel dissipate. Ans: Unlike induction-powered heaters, the control units do not dissipate power except as lighting (negligible as the MHI panels use LED lights) or from the SCRs when firing at less than 100% power.