Use the Airtorch ad Steam for Powder Metallurgy Furnaces, Chemical Reactors, Fluidized Beds, Debinding Furnaces and Powder Cleaning Devices. Such Devices are Generally Custom Built.

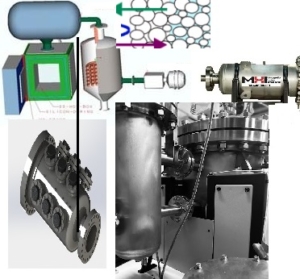

| Airtorch Convective Heaters Airtorches are used whenever hot gas/air is required in various powder operations. Choose from LTA, AT, or Ultra Models. Recirculating is available on several models. Please click here Customized builds to reaction beds and catalysts covered ceramic balls and scaffolding with coatings. | Customized Solutions. Several Options with Airtorch Steam and Furnaces.

| |

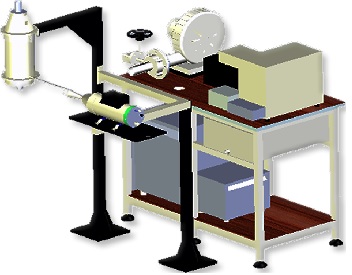

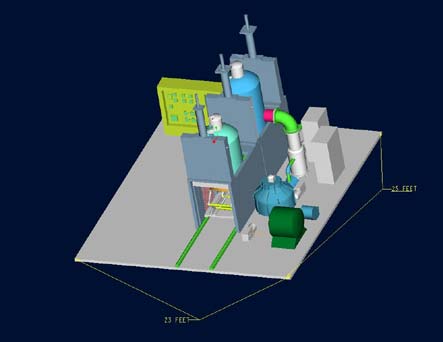

| Austempering Martempering Fluidized Bed Fluidized beds are used for the heat treatment of parts. MHI fluidized beds use unique fractal materials for best uniformity and employ efficient Airtorch to produce hot air or gas.  SaniZap. For Air Steam mixture for small fluidized beds |    | Several Options: Please call MHI to ask about the chamber’s size and the operation’s temperature. Please call MHI for detailed specifications and prices. For steam generators click to Steam

|

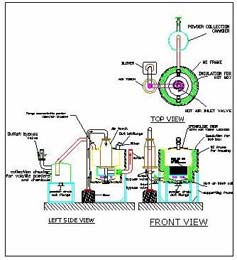

| Hot Powder Cleaning Spray-dried powder surfaces often have to be hot cleaned with gases. Sometimes, hot air exposure is required to round off powder surfaces. MHI offers several systems for powder conditioning and cleaning operations. Please call for specific solutions. | Several Options: Please call MHI to ask about the size of the chamber and the operating temperature. Please call MHI for detailed specifications and prices. | |

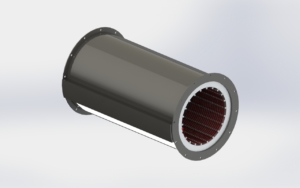

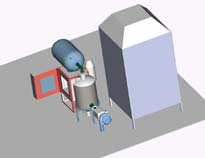

| Debinding Furnace with Flowing Gas MHI offers low-price, one-atmosphere flowing debinding systems. Recirculation of gasses is possible in such systems if the debinding is done in flowing argon or similar atmospheres. |   | Several Options: Please call MHI to ask about the size of the chamber and the operating temperature. High surface area ceramic clinkers are available; see Fractal Balls. |

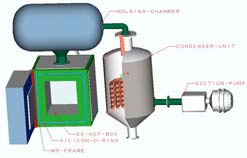

| Debinding and Sintering Furnace Models MHI offers sophisticated integrated debinding and sintering furnaces when debinding requires partial pressure and when sintering requires a vacuum. Call MHI for details. |  | Several Options: Please call MHI to ask about the size of the chamber and the operating temperature. Ask for models beginning with the letters DSF for these furnaces. Common Models are DSF1200C(10x10x30) or DSF1200C(48x48x10). |