Description

LTA-12V |

|

| Model: | LTA 12V Cartridge Type Hot Air Gun (inline type)  |

| Unit Description: | Model LTA-12V belongs to the Airtorch series of inline hot air tool devices with continuous hot air discharge of 800°C.

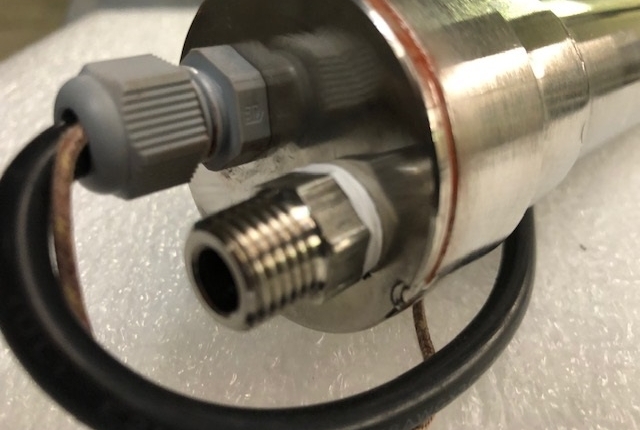

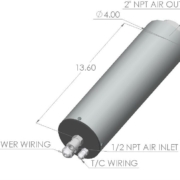

Such hot air guns find application in plastic welding, heat shrinking of thermoplastics, ceramic drying, on-site heat treatment, plastic forming, and many more inline uses. The unique shell construction provides for efficient heat recovery and management, For 90-120 W, a minimum flow of ~5 slpm is required if feedback controls are not used. The expected temperature is between 600-800°C at 12V plug-in at ~5 slpm@ full power. A higher flow will reduce temperature. A lower power will reduce the temperature. Note: Parts of the surface are hotter than 50°C (DO NOT TOUCH). This unit is for inline stand-alone use. The air gun has an in-built Type “K” thermocouple and an available temperature read-out (optional). Flow generation is with a compressor and flow meter, both in the user scope. Plug and play. Unit: 1.5″ dia x ~6″” L (collar is 1.95″ dia) |

| Dimensions: |

Air inlet: 1/4″ NPT male fitting |

| Weight: | Lightweight with a compact, ergonomic design |

| Temperature: | Expected 800°C continuous airflow |

| Airflow: | 5 SLM |

| Voltage: | 12V (AC or DC) |

| Frequency: | 50/60 HZ |

| Current: | Approx. ~10 Amps @ 12VAC |

| Power Consumption: | ~120 Watts |

| Output Power Control: | Remove plug – no switch provided |

| Handle: | None. |

| Optional Accessories:

TC READ (Pictures shown above) |

Note the unit has its thermocouple. This product has a power of ~120 watts.

The Built-in thermocouple can also be connected to the optional TC Read system for an external display. The TC-Read unit plugs into a 115/120V single-phase socket. 3 1/2″ LCD display switchable between °C and °F (TC Read) |

A MINIMUM AIRFLOW REQUIRED FOR SAFE USE IS REQUIRED. The LTA’s are not fully sealed. FULLY sealed units are MTA models. Please link to the LTA page for more information. Note that close to the maximum rated i.e., ~5 SLM and close to 10-12V, and no feedback loop control, the user has to be careful to ensure that there is no burnout.

MHI Inc. USA

MHI Inc. USA MHI Inc

MHI Inc MHI Inc. USA

MHI Inc. USA

MHI Inc. USA

MHI Inc. USA