Description

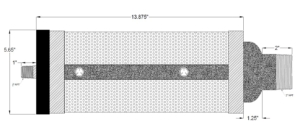

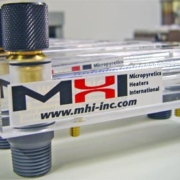

MHI MTA925-04 is a Process Air/Gas Heater (4kW). This is a one-atmosphere sealed system for heating various non-combustible gases. Long Life models. Dimensions are about 18 inches long and 5.5 inches in diameter. Use in the temperature range of 200°C to 950°C.

For the home page for Airtoch models, please click here.

For MTA925 models, a BPAN-O-PLUS and a flow meter may be required to adjust flow and power.

Exit: Threaded exit nozzle 2″ NPT Male.

Inlet: Threaded inlet nozzle 1/2″ NPT Male.

When selecting a flowmeter, please indicate the gas type in the remarks column.

Continuous Hot Air/Gas Discharge up to 925°C (Nominal for Air with 60C input and maximum power).

The maximum temperature limit is 950°C. Maximum power varies with socket voltage. Please see below. For use beyond 850C, a proper flowmeter and a BPAN-O-PLUS are highly recommended.

Flow Rate and Temperature: At 4KW power, Air or Nitrogen: Typically ~ 6.5 SCFM for 925C for Air.

Maximum Power: 4 kW Total Power (Nominal @ 240V). This is the power at 240 V supply conditions. If the supply is 208 V, please note you will only obtain a maximum of ~3.3 KW.

For 230 V, the power draw will be ~3.9 KW.

Stainless Steel Shell Construction. ~1 Atmosphere use only.

Built-in “K” Type Process Thermocouple

Plug-In Design. Use 208/220/230 or 240V, 50/60Hz. Wiring to unit provided (wall connection plug is local scope)

Ready to Use. This Airtorch® is for use only for non-combustible gases and non-reacting gases like Air, Nitrogen, Argon, and mixtures of non-reacting gases. Input gas should not exceed ~60°C.

Units are sold only for non-combustible, non-pressurized, and non-ignitable/non-reactive gases and mixtures. If used for steam or steam mixture, please indicate in the remarks column during checkout. Only dry noncondensing input steam gas is allowed.

The Optional Mixer Nozzle (not always available) provides gas inlets at the Airtorch® exit—three-way input. The nozzle is insulated with insulation.

Total Power and Flow Controller Options Available

No brackets are provided. A horizontal saddle or bracket is in the user’s scope.

Independent power and flow control is available (optional).

BPAN-O-PLUS models have temperature and over-temperature control. If required, choose UL or cUL for the Canada option for the BPAN-O-PLUS Panel.

The minimum flow rate should be maintained. MHI BPAN-O-PLUS power controllers can be used to set temperature and or power.

- * Please note that mass flow meters are recommended when operating above 800°C. Float gas meters are not as accurate as mass flow meters. Float gas-type gas flow meters must be used with the float valve indicator that is accurate in the 6.5 – 16 SCFM for operations close to the maximum rated temperature.

- The outside shell temperature depends on the shell position. Towards the exit, the shell may be hot to the touch. The user is encouraged to work with the proper safety gear.

- * Please note that the shipping price is an estimate commonly quoted only for US shipping. Your acknowledgment may contain an amended shipping price that reflects a more accurate price.

- Model: MHI Model# MTA925-04

Temperature: 950°C Maximum Continuous (Minimum airflow to be maintained). Temperature measured by internal TC before nozzle exit. Exit temperatures are highly dependent on the application and use conditions.

Thermocouple: Built-in K-type thermocouple. It can be linked for external display (TC-READ) or full control (BPAN Control Panel).

Element Installation: Factory installed. Heating elements can only be serviced at MHI-approved locations, where applicable. Please contact your MHI sales representative for the service program and details.

Wiring Requirements: 240 Volt, single-phase @ 50/60Hz, 18 Amp Max current. It may be used with 208V, 230V or 220V input. Maximum power will vary with line voltage.

Power Consumption: 4 kW (Nominal @ 240V). Slightly lower power and temperature for 220V.

Frequency: 50/60 Hz

Air-Source: Via compressed air or compressed gas sources (e.g., Nitrogen / Argon). Approximately ~6.5 SCFM is the minimum airflow (compressed air) required when operating the device at full power to achieve maximum temperatures. A compressed air source is not included and is within the user’s scope. Please contact MHI for assistance. - Gas Source: User Scope. Not to exceed 60°C at the inlet.

Inlet: 1/2″ NPT Male. Inlet gas not to exceed 60°C

Outlet: 2” NPT Male

Optional:

Power Control: Optional: MHI BPAN™ or BPAN-O-PLUS-220 Control Panel. Single Phase Controller. Includes on-off switch, thermocouple readout, and PID controller. Advanced phase- anglefired SCR with soft start and current limiting features integrated for device protection and control. BPAN -O-PLUS-220 has an over-temperature controller—display: Either BPAN-O-PLUS Control Panel or Not Included. The built-in thermocouple can be linked for external display on optional product TCREAD basic display. Optional: 3 ½ LCD display switchable between °C and °F

Flow Control: Optional: FLM flow meter for basic pressure flow control. Setting range suitable for 4kW. Please indicate Gas in the remarks column. SCFM readings.

Controls: Can I use my own? Generally, it’s not an issue if you have experience. Please ensure you have an over-temperature cut-off and soft start features as the BPAN-O-PLUS offers. This is particularly important when using close to the maximum rated temperatures. Sealed units cannot be repaired if a burnout occurs. The heaters have no warranty when used with non-MHI controls or if control features are disabled.

With the BPAN-O-PLUS, a cUL or UL option is also offered.

BPAN-UL

Efficiency. Flow chart to consider: https://mhi-inc.com/airtorch-design-graphs/. It is a general guidance chart not specific to your device. Also, there could be slight variations of the nominal resistance or air flow provided by flow meters (even mass flow meters).

Can I use it in a hot enclosure? The temperature of the outside cannot be more than 80°C.

My down-the-line TC is lower than the unit TC. Does the temperature drop in an attached pipe? Yes, unless the exit pipes are very well insulated, a temperature drop can be expected.

Experimental results and modeling of energy storage and recovery in a packed bed of alumina particles,

Applied Energy, Volume 119, 2014, Pages 521-529,

https://doi.org/10.1016/j.apenergy.2014.01.030.

MHI Airtorch™

L.S. Distinguished Senior Tech at National Laboratory, USA

You are the Best! Thank you very much for your support.

R.S. Ohio

“We purchased the 10kW Airtorch™ to perform rapid cycling tests to qualify our product for a new customer. We have secured the contract and the Airtorch™ is still going strong for 2 years. We are now using it for new development projects.”

See use picture

J.M. of Morgan Tool

“Using the LTA as the primary heat source for my customer’s tool turned out to be a wise decision. It’s robust for continuous use in a shop floor environment.”

C.A., UK (International)

I am very satisfied with the Airtorch™; we operate it everyday between 1100 and 1200°C for our experiments.

EL, National Lab, USA

“I really like the LTA … very much. They are incredible! As per my calculation, we are seeing (very high) efficiency…”

Nate M, Utah

“We added the 15kw Airtorch to our existing Gas Tunnel Kiln to improve uniformity and overall drying time. It was cheaper than buying a new kiln”

Paul F, Pennsylvania

“We’ve used the Airtorch™ as a pre-heater for our application. It works well, we bought two…”

Ron J, Ohio

Finally, a product for die heating that really meets our needs!”

Tim D, Ohio

“Airtorch™ is a great concept, it works well for my unique applications…”

Ken F, Tennessee

“This hot air device offers great versatility, its the device I’ve been waiting for…”

Jim V, Michigan

“This device will save us money.”

MHI Inc

MHI Inc

MHI Inc. USA

MHI Inc. USA

MHI Inc. USA

MHI Inc. USA

MHI Inc. USA

MHI Inc. USA