High Energy Efficiency, Zero Emissions, and Better Process Consistency with the Airtorch® and MightySteam® – What you should consider for project analysis that includes thermal processes.

“The health impacts of combustion-related emissions are not speculative or future-dated. They are observed, quantified, and repeatedly reaffirmed by public‑health agencies and the IPCC. Eliminating combustion reduces exposure risk today, independent of any carbon pricing”.

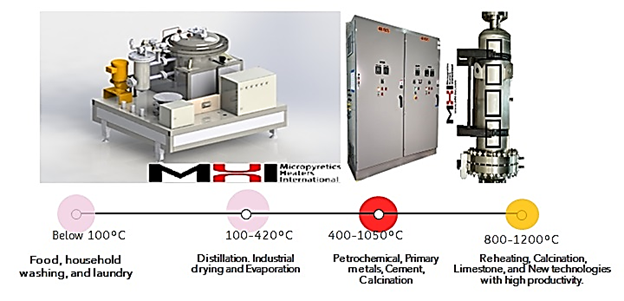

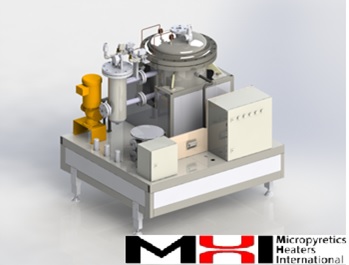

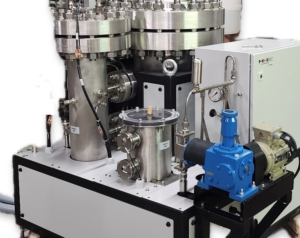

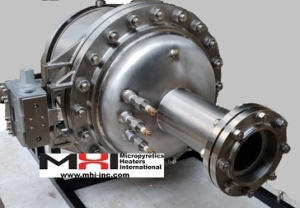

Process Gas Heaters, Electrical Process Steam®, E-Ion®, Large Radiative Panels, , and Large Furnaces

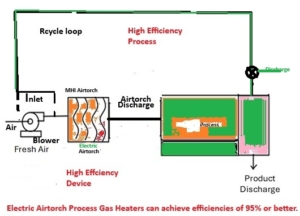

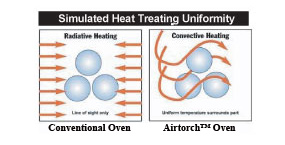

Summary: Energy efficiency and productivity greatly impact the payback period and overall returns for any investment. Energy efficiency is an essential measure of how we utilize and pay for energy. It is best to use electricity for heating, as electric heaters are substantially more efficient than fossil-fuel heaters. Electric-powered process heat or steam generation systems do not incur flue gas, excess radiation, or heat exchanger losses from indirect heating. Productivity (i.e., parts produced per unit time) tends to increase with greater thermal uniformity and higher processing temperatures. Precision control is easier to achieve with electric heaters. Electric heaters permit the recycling of heated gases.

How we use energy is just as important as how we generate electricity. Products with advanced automated electric heating solutions, such as the Airtorch®, MightySteam®, E-Ion®, Large Radiative Panels, and Large Furnaces, improve energy efficiency, operational performance, and uniformity, significantly boosting productivity. The current volatility in climate and weather events is expected to lessen as Earth’s warming slows, which is possible with reduced emissions through energy-efficient industrial heating and electrification. MHI Inc. recognizes that electrifying industrial heating systems offers a key opportunity to achieve substantial energy savings and deep decarbonization with zero emissions. The focus on the effectiveness of decarbonization must consider not only how we produce electricity but also how we use it. In today’s rapidly evolving industrial landscape, the urgent need to decarbonize, improve energy efficiency, and advance sustainability has become a central priority for businesses worldwide. Electric Solutions for Improving Process Performance and Reducing Costs with Energy-Efficient Heaters.

Any reduction in greenhouse gas (GHG) emissions is beneficial. Industrial Choices.

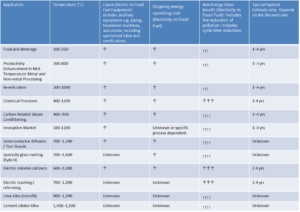

The gamut of decarbonization products across a range of application temperatures.

At a Glance

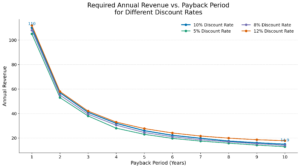

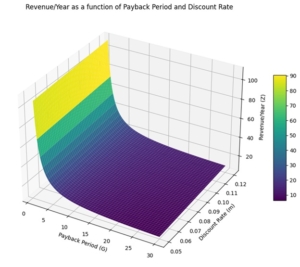

Here is a an approximate chart for the payback period based for high efficiency thermal equipment based on the discount period and revenue generation for $100 invested.

Typical Emissions from Fossil Fuels (4.17-6.99) × 10-4 metric tons of CO2/kWh. The social cost of this is anywhere from $50-3000 per ton of CO2eq.

The five major key greenhouse gases are carbon dioxide, nitrous oxide(s), methane, chlorofluorocarbons, and water vapor. The most concerning being carbon dioxide, methane and nitrous oxides.

Still considering fuel fired heaters? Don’t forget to include ancillary equipment (also called BoP – Balance of Plant) adders:

Capex adders

- Fuel delivery & pressure control (piping runs, meters, PRVs, K.O. pots)

- Burner trains & BMS (valves, flame scanners, purge/combustion air, control panels)

- Stack & ductwork (penetrations, dampers, dilution air, structural steel)

- Gas detection & ventilation (sensors, fans, interlocks, alarms)

- Electrical area classification (Class/Div fittings, sealing, wiring changes)

- Engineering & permitting (stamped drawings, NFPA reviews, emissions permit)

- Commissioning & tuning (burner setup, stack tests)

Opex adders

- Emissions testing/reporting (stack tests, consultants, Title V/TRI where applicable)

- Annual burner tuning, safeties proof‑testing, LDAR where required

- Insurance/coverage deltas for combustion/explosion risk

- Unplanned outage exposure from combustion trips (spare parts + labor)

Economic: Electric methods are generally more efficient than fossil fuel combustion for heating. However, it is crucial to use the most efficient electrical systems. Improving energy efficiency can lower utility bills, create healthy jobs, help stabilize electricity prices, and benefit the climate by reducing CO2 emissions for any goal. Several attractive loans are available to help reduce human-caused carbon emissions through new equipment, such as lowering emissions of various carbon forms, primarily carbon dioxide, related to human activities. These activities include burning fossil fuels, deforestation, land use changes, livestock, fertilization, and more, all leading to a net increase in emissions. The payback period for new decarbonization equipment is quite short when considering the high social cost of CO2 emissions from alternative methods. Contact MHI for your decarbonization system needs (free). In the literature we are able to find values for the social value of CO2eq between $0- $5000 / ton of CO2 eq. Internally we typically choose value from $51 to 283/ton of CO2.The science linking anthropogenic emissions to health has very high confidence based on IPCC, WHO. The IPCC’s Sixth Assessment Report (AR6) states with very high confidence that climate change has already adversely affected physical and mental health globally, and that the net impacts are negative at all scales. These conclusions are based on thousands of peer‑reviewed studies and observed health outcomes, not forecasts alone. [ipcc.ch], [ntrs.nasa.gov]

Key impacts with observed evidence:

- Increased heat‑related mortality

- Worsening air‑quality events (Ozone & PM episodes)

- Expansion of vector‑borne diseases

- Increased food insecurity affecting nutrition

- Measurable mental health impacts after extreme events

Air pollution pollution has the most direct and least controversial linkage. From a corporate risk standpoint, air pollution is the strongest bridge between emissions, health, and liability.

Particulate matter (PM₂.₅) & NOₓ

- Fine particulate matter from fossil fuel combustion penetrates deep into lungs and the bloodstream, increasing cardiovascular and respiratory mortality.

- There is no known safe threshold for PM₂.₅ exposure. [epa.gov]

Ground‑level ozone

- Formed from NOₓ and VOCs in heat and sunlight.

- Associated with asthma attacks, ER visits, lost workdays, and premature death. [cdc.gov], [document.airnow.gov]

WHO estimates:

- ~7 million premature deaths per year globally are attributable to air pollution, making it one of the leading risk factors for disease worldwide. [news.un.org], [who.int]

This is why health agencies frame air pollution as a public‑health emergency, not an environmental side issue.

Climate change amplifies pollution‑related health harm

Climate change doesn’t just add new risks — it multiplies existing pollution risks.

- Higher temperatures increase ozone formation.

- Heat and drought increase wildfire PM exposure.

- Climate change lengthens pollen seasons and increases allergenicity, compounding respiratory illness. [who.int]

The CDC explicitly links climate change to increased ozone and PM‑related premature deaths in the U.S., with thousands of additional deaths per year projected without further controls. [cdc.gov]

Economic and healthcare system impacts (often overlooked). The Lancet Countdown, produced with WHO participation, tracks climate and health using 57 indicators and shows:

- Heat-related deaths have increased 23% since the 1990s to 2024

- Hundreds of billions of labor hours lost annually due to heat exposure

- Health system costs rising from pollution-related chronic disease

- Six-figure USD value per avoided premature death frequently used in national assessments [who.int], [lancetcountdown.org]

This is where your instinct is correct: many costs never appear on corporate balance sheets but absolutely show up in societal and health‑system accounts. T US government agencies use a variety of VSL values. Value of a Statistical Life (VSL) figures used by U.S. federal agencies for regulatory impact analyses have generally converged to a range of $6 million to $12 million+ (in 2020–2023 dollars), though specific figures vary by agency and the year of the analysis. See latest HHS numbers here.

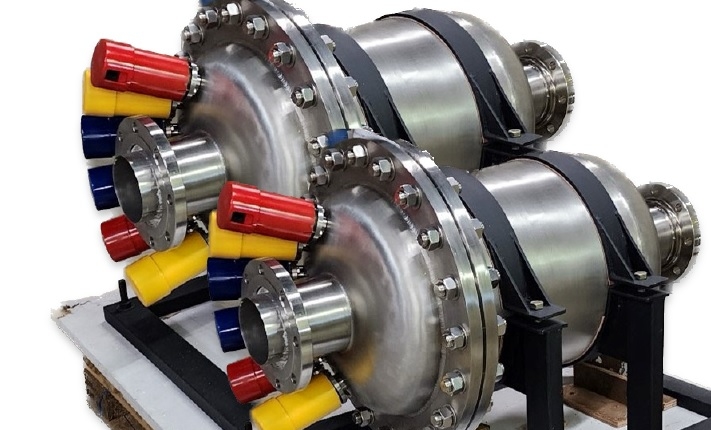

Airtorch®, Steam and other Energy Efficient Products with High Payback Benefits.

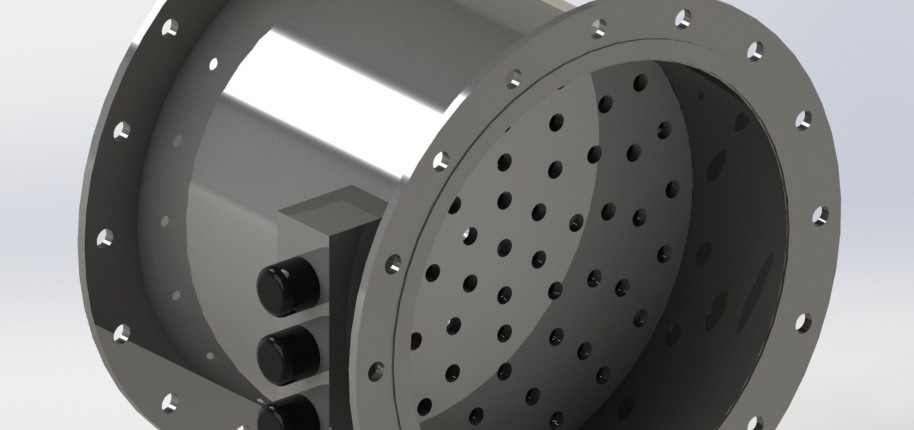

Please use a five-step process for selection. First, choose the maximum rated exit temperature of the Airtorch®. If below 900 °C, please select TA models, e.g., VTA . If above 925°C, please choose the MVTA or DPF model – please contact MHI.

Sometimes, the lowest power users work through several cycles in a recuperator mode. The SH models can accept inlet gas temperatures up to 800°C. Please get in touch with MHI for details.

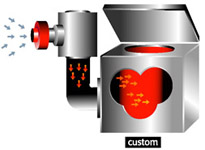

The Airtorch® convective system uses a particular class of elements to heat the ambient air and direct that heated air towards a surface or into a chamber. Depending on the model, the Airtorch® system can achieve temperatures ranging from room temperature to 1100-1200°C (~2200°F) with infinitely variable volume flow rates and no harmful emissions, providing a beneficial new heating method with modern controls.

MHI Airtorch® applications are in drying electrical varnish, weld preheating, die heating, plastic softening before forming, drying motor parts, removing moisture, expansion fitting, combustion, simulation preheating and heating molds, curing, prosthetics, heat shrinking, compression molding, flock setting, curing catalysts drying slurries, freeze-drying, improving ink print finish, finishing mirror drying, latex, heating adhesives, and general heating of chambers as shown below. Add to chambers for powder and liquid finishing. Add to continuous furnaces for wood conditioning, metal finishing, and forming. A small but finite temperature drop is experienced when directing Airtorch® flow with insulated piping because of the high velocity.

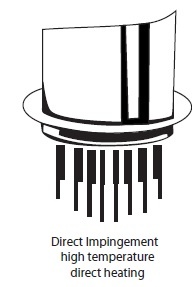

- For impingement types of applications, the DPFs offer very superior value.

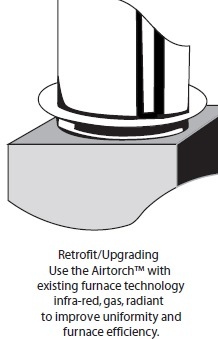

- A good rule of thumb for augmenting uniformity in an existing furnace with an Airtorch® add-on is choosing an Airtorch® power with at least 30% of the original. This may not be enough if a temperature increase is also sought.

- When planning to extend the Airtorch® exit piping, please note that well-insulated pipes will drop the temperature very little as the exit velocity is m/s. A helpful but rough rule of thumb may be about 50°C-100°C/m drop for good internal pipe insulation. Good pipe insulation is specific to whether the pipe is internally or externally insulated. The MHI industry standard is about a 1-2″ thick insulation. Please get in touch with MHI when required.

Introduction to Airtorch® | Airtorch Applications | Calculate Power .vs Flow Rate | Easy Design Criterion

With its variable volume flow rate and power adjustability, the Airtorch can be set up to perform at any condition of flow temperature under the curve. Such features offer the user maximum flexibility when applying the Airtorch™ technology to heating applications.

Easy to use selection and design page.

cleaning and degreasing

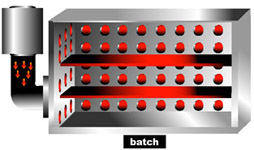

The use of Airtorch® products may be classified into three major categories schematically drawn below. In addition the Airtorch® can be used inline and cross line. MHI is a specialist in inline, offline and cross line Airtorch and other similar systems that heat air and gases to high temperatures.

Direct Impingement |  Gas Preheating |  Retrofit for Enhancement |

Retrofit/Upgrading.

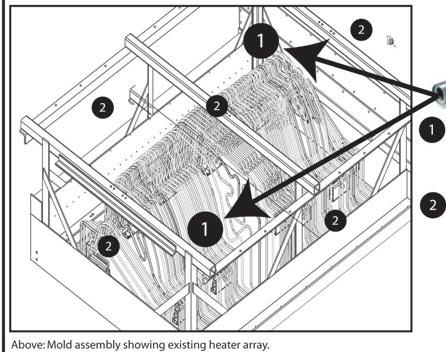

Example of Use to Augment an Existing Furnace Installation for Improved Power and Uniformity.

An example of a 4kW Airtorch® augmentation application is schematically shown below. In this application, many complex-shaped rods are to be heated uniformly. The heat-treater reported that the rods were not uniformly heated in his existing radiant heat furnace. MHI proposed an add-on to his existing furnace with a system of Airtorch products, significantly impacting the uniformity – reducing the total energy consumed. More Green Installation and more Profits to the user. Improve oven performances and eliminate harmful emissions.

A uniform surface heating retrofit example and continuous oven examples are illustrated below.

As a rule of thumb, an Airtorch power of ~0.3 the furnace power is employed when designing for better uniformity.

CFO Checklist:

CFOs and project finance decision-makers are using a checklist that accounts for emissions risks over the future period, when the equipment will incur emissions costs, as widely expected. CFO PowerPoint pitch.

- Quantify temperature band & duty cycle (load factor). Higher temps usually → faster SPB/stronger IRR.

- Map losses in the current fired system (stack, radiation, cycling). Converting these into useful heat is the core savings engine.

- Price water & compliance (permits, NOₓ/CO₂ handling). Include the internal carbon price if used in hurdle‑rate reviews. Internal carbon pricing could range from $51 to $ 3,000 per ton of CO2-eq.

- Evaluate waste‑heat reuse (HX, preheats). It moves payback left.

- Procurement options (off-peak/TOU power, RE PPAs). Stabilize long‑run LCOH and hedge gas volatility.

- Factor in potential legal liability of emissions.

Electrification is one of the fastest routes to dramatically increase energy efficiency and impact decarbonization. It has the potential to significantly reduce costs and lower greenhouse gas emissions in the chemical production, test beds, calcination, drying, refining, fuel production, general manufacturing, shipping, and iron and steelmaking industries.

Eliminate GHG emissions: Assuming a cost of emissions of $283 per ton of CO2 emitted, burning fossil fuels for heating could add approximately $0.1 to $0.15 per kWh to the energy cost of fossil fuels. Globally, August 2025 was the third-warmest in NOAA’s 176-year record, with a temperature 1.93°F (1.07°C) higher than the 20th-century baseline.

Another way to consider this is as follows: Replacing a 6 MW fuel-fired unit with an MHI efficient electric heater could result in a reduction of 5 tons per hour in CO2 emissions. Therefore, at the lowest emission tax savings (see adjacent column), equivalent to approximately $51 per ton (which could be higher), this results in savings of nearly $190,000 per month. An energy-efficient system also reduces energy costs, depending on the fuel and electricity rates per kilowatt-hour (kWh). If the price is approximately 14 US cents per kWh for both fuels, then assuming a 50% increase in efficiency for an electric 6 MW system, the monthly energy savings could be $300,000. Read More…..

A UN report states that fossil energy sources account for over 75% of global planet-warming pollution and nearly 90% of all carbon dioxide pollution. Several countries have set ambitious goals. The US climate goals (goals set in 2023/2024) are to reduce greenhouse gas emissions to below the 2005 levels by the year 2030 – a step towards a sustainable future (source). The goal requires a 50% reduction in current emissions. The further goal of achieving 100% carbon pollution-free electricity generation by 2035 and a net-zero emissions economy by 2050 underscores the urgency of action. The United States has made significant strides in its climate and energy policies aimed at reducing carbon emissions. As of 2023, 194 sovereign states, representing over 98% of the global greenhouse gas-emitting regions, including the US and the EU, have ratified or acceded to the Paris Agreement. Such global cooperation indicates the shared responsibility in combating climate-changing emissions of CO2 and other greenhouse gases (GHGs). However, the industrial sector must also do its part if the goal of 1.5°C is to be met (the Paris Agreement target).

The International Energy Agency estimates that to achieve carbon neutrality by the middle of the century, global investments in renewable energy must triple by 2030, reaching over $4 trillion annually (cited from a wiki source).

Due to the health and climate problems associated with GHG emissions, it is essential to ensure that GDP and firm-level growth can increase even as fossil fuel use decreases, primarily through improvements in energy efficiency and the adoption of electric technologies. The International Court for Justice ruled in July 2025 that countries can sue other countries for climate emissions. It is a non-binding ruling, but the directions that countries must adopt to prevent carbon emissions are clear.

Solution

Choose from electric Airtorch, Steam, or Radiative panel products to eliminate GHG production. Often, electricity (electric energy) is almost free of charge.

Case Study: Aluminum melting requires 397 kJ/kg of energy, but many fossil fuel direct furnaces are only about 13% efficient. Energy efficiency could be improved five times by using electric methods, e.g., Airtorch.

Case Study: A reduced coking tendency and higher conversion temperatures can be expected while converting Naphta (cracking) or similar compounds to simpler olefins or more valuable, smaller molecular fuel. Contact.

![]() Power conversion MW to Btu/hr (Multiply by 3412142)

Power conversion MW to Btu/hr (Multiply by 3412142)

| 0.01 MW | 34121.42 BTU/h |

| 0.1 MW | 341214.2 BTU/h |

| 1 MW | 3412142 BTU/h |

| 2 MW | 6824283 BTU/h |

| 3 MW | 10236420 BTU/h |

| 4 MW | 13648570 BTU/h |

| 5 MW | 17060710 BTU/h |

| 6 MW | 20472850 BTU/h |

| 7 MW | 23884990 BTU/h |

| 8 MW | 27297130 BTU/h |

| 9 MW | 30709270 BTU/h |

| 10 MW | 34121420 BTU/h |

Ask MHI about compact KW to MW electrical systems. MHI products for heating and steam do not use any fossil fuel nor emit greenhouse gases. Using fossil energy like fuel oil, gasoline, or natural gas for heating creates considerable CO2 and other greenhouse gases. Every ton of CO2 emission causes about the same amount of global warming, no matter when and where the CO2 is emitted. (Free calculator).

Why is there so much efficiency gain with electrification compared to fossil-fuel heaters?

This is mainly related to inherent thermal energy loss from flames (short wavelengths) and the natural inefficiency of heat exchangers. Conventional drying is an open process where flame radiation causes heavy energy losses. When drying is done by directly heating the bed with combustion burners, the flue gases take away a lot of energy. There is a 20% to 50% loss when heat exchangers are employed. Without a heat exchanger, the energy efficiency is always better. Ask MHI about Waste Heat Recovery (WHR) Systems.

Specific fossil fuel emissions of CO2 per GJ of heating specific fuels.

| The heat value of fuels (MJ/kg of fuel) | |

| Natural Gas (the main component is methane). Heat value 42-55 MJ/kg. | 50.4 – 56 kg of CO2 per GJ |

| Jet Fuel Heat value 50-55 MJ/kg. | ~68.8 kg of CO2 per GJ |

| Bituminous (coal) Heat Value ~ 18 MJ/kg. | 88.8-100 kg of CO2 per GJ |

| Diesel and Home Heating Fuel (Distillate Fuel Oil) Heat Value 42-46 MJ/kg. | 59.9-69.3 kg of CO2 per GJ |

| Gasoline and Ethanol Blends. Heat value 44-46 MJ/kg. | 64.1 -72. 5 kg of CO2 per GJ |

- The tropospheric entropy generation rate (EGR) is already high and increases with temperature.

- On average, one ton of CO2 requires fossil fuel to burn approximately 4 million kJ.

- About two ppm of CO2 is added to the troposphere annually by fossil fuel combustion. This significantly raises the production demand of the tropospheric entropy density rate by almost ~ 10−8 J/(m3.K.s.ppm(CO2)). Citation.

- One industrial process heater using fossil fuels (15MW) could use 245 Billion BTUs for a year. That corresponds to a lot of CO2 production—about ~100,000 tons or more of CO2 emissions from one such large industrial dryer yearly!

- The social (environmental) cost of producing/emitting CO2 gas varies—several hundred dollars per ton of CO2 emitted—and is climbing rapidly (Source).

- Climate change impact impacts the cost of a project. Companies today include the environmental cost in project economics calculations.

- Thus, the social cost of using a carbon-containing combustible gas could substantially increase the price of combustion fossil fuel projects.

- Did you know that Modern Electric Heating methods Eliminate CO2 Emissions?

- How much CO2 can I save by going electric? A 10 MW decarbonized machine can prevent several Tons of CO2 emissions every hour. See more…(pdf format)

- So why not go electric? Electric heating is more efficient for energy use in addition to zero GHG emissions benefit. An excellent place to start is industrial decarbonization. Save energy with efficient electric systems.

The Gamut of Airtorch Products

A fuel’s “Heat value” is the heat released during combustion. Also referred to as energy or calorific value, the heat value measures a fuel’s energy density and is expressed in energy (Megajoules or Gigajoules) per (kg). If the fuel contains carbon, there is CO2 emission, as shown in the table above.

| Fuel | Heat value |

| Hydrogen (H2) | 120-142 MJ/kg |

| Methane (CH4) | 50-55 MJ/kg |

| Methanol (CH3OH) | 22.7 MJ/kg |

| Propane (C3H8) | 46 MJ/kg |

| Dimethyl ether – DME (CH3OCH3) | 29 MJ/kg |

| Petrol/gasoline | 44-46 MJ/kg |

| Diesel fuel | 42-46 MJ/kg |

| Crude oil | 42-47 MJ/kg |

| Liquefied petroleum gas (LPG) | 46-51 MJ/kg |

| Natural gas | 42-55 MJ/kg |

| Hard black coal (IEA definition) | >~23.9 MJ/kg |

| Hard black coal (Canada) | ~ 25 MJ/kg |

| Sub-bituminous coal (IEA definition) | 17.4-23.9 MJ/kg |

| Sub-bituminous coal (Canada) | ~ 18 MJ/kg |

| Lignite/brown coal (IEA definition) | <17.4 MJ/kg |

| Lignite/brown coal (Australia) | c. 10 MJ/kg |

| Firewood (dry) | 16 MJ/kg |

| Natural Uranium in LWR with U & Pu recycle | 650 GJ/kg |

| Natural Uranium, in FNR | 28,000 GJ/kg |

| Uranium enriched to 3.5% in LWR | 3900 GJ/kg |

Steam OAB Unit 360 view Video (download).

A uniform surface heating retrofit example and continuous oven examples are illustrated below.

As a rule of thumb, an Airtorch power of ~0.3 the furnace power is employed when designing for better uniformity.

EFFICIENCY

| Electric Systems Offer Design Improvements / Enhancements | ||

| Combustion/Flame | MHI Electric Systems | |

| Appearance | Non-uniform heating. | Repeatable uniform heating – resulting in consistent label results. Once conditions are dialed in, the setup will yield minimal variation. |

| Bottle or Treated Surface | Combustion leaves deposits on the surfaces (visible to micro level) | Airtorch® or Steam or Steam/ Air patented heating leaves no combustion product on treated surfaces. Improves detail and appeal. |

| Sources | Combustion source creates: Explosion hazard Costly fuel and disposal Emissions of CO2 from combustion ‘Hot’ spots from flame heating Venting required | Electric Systems: Electric flexible source. Air or Water No emissions No combustion Evenly distributed heat No explosive consumables |

SUSTAINABILITY

| Modules for a Green Work Environment | ||

| Combustion/Flame | MHI Electric Systems | |

| Modularity | New gas lines, more consumables used, safety approvals, etc. | Modular with flexible power lines as needed. You can add and subtract modules in minutes. Easy to install Easy to operate Easy change of configuration Highly mobile |

| Repeatability | Non-uniformities result from combustion treatment surfaces— uneven heating, combustion deposits, NOx, SO2, and more. | Electric systems offer uniform, repeatable, and continuous treatment of products resulting in less variance. |

| Control | Lack of precise control from combustion is a problem. | Precise control of temperature and output gives high efficiency to your process. A high level of control also allows for protection features such as overtemperature protection. |