Description

Process Air Generator. Hot air or gas generator. It can be used with air, nitrogen, inert gases, and CO2. For FULLY sealed 10 kW models please click here

Model: LTA750-10 (The plug-in voltages are 208/220V /230V/240V single phase). The power draw at 240V (single phase) is 10 kW. For a 208 V (single phase) it is 9 kW.

The maximum power from this unit is 10kW 50/60Hz for a 240V (single phase) input. With 10 KW ~23 SCFM, air from 25 C can be heated to 800C (~25C input).

The maximum power from this unit 9kw 50/60Hz for a 208V (single) input.

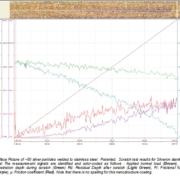

Temperature: Typical use is for ~(40 °C – 850°C). The temperature can be controlled with the control panel (if purchased) or with gas flow. The optional control panel has contactors, phase angle SCRs, and displays for the temperature, over-temperature, and current display. Both the temperature and power can be adjusted with a HIPAN/XPAN control panel. The SCRs can be adjusted for the current limit.

Inlet temperature not to exceed 60°C.

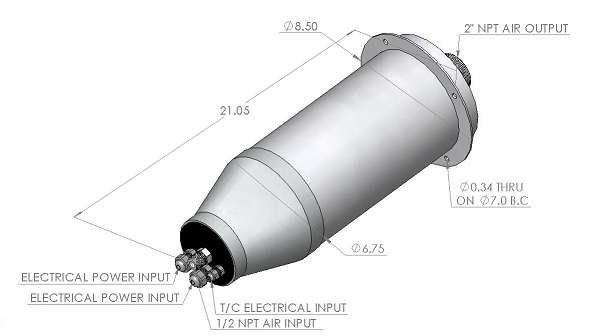

Unit Description: Custom LTA Airtorch® Heavy Duty Industrial Air Heater System Model LTA750 series is an inline air heater with continuous hot air discharge up to 850°C continuous use. Outlet 2″ NPT. Inlet 1/2″ NPT male (see product images). The picture shown may be illustrative only. Outlet 2″ NPT. Inlet NPT male. The picture shows a 9″ Diameter (at flange) and 22″ Long envelope. Pictures also show outlet and inlet, power chords, and T/C wires. Note that the unit is a plug-in with a minimum flow of 18 SCFM air (i.e., at full power).

Lower temperatures are obtained by flowing more gas or using the HIPAN/XPAN control panel described below.

Not rated for gas Input beyond 60°C (maximum inlet temperature). The unit is not rated for liquid or mixed phase inputs. The pictures below show a schematic of the unit and a UL508A XPAN.

Note: Parts of the surface are hotter than 50°C during use. The Airtorch® has an installed Type “K” thermocouple as a standard.

A compressed air gas source is connected to the flow meter, which regulates flow into the LTA. Please use accurate flow controls when operating above 700°C. The rated KW, voltage, or temperature should not be exceeded at any use time. Please note that the LTA and MTAs products require a flow meter or similar device to set the correct flow for use and ensure minimum flow when operating above 750°C.

Unit Features:

- Stainless Steel Shell Construction

- Built-in Type K Thermocouple

- Lightweight with a compact, ergonomic design

- 208/220 or 230/240V plug-in design

- Rapid heat-up

- Compressed Air/Gas compatible

- Inlet gas not to exceed 60°C

- Outlet 2″ NPT. Inlet NPT male

- Inlet 1/2″ NPT.

- 1 Bar use.

- 208-240V 50/60Hz (Single phase). The 240V is required for the highest temperature and power. Please follow local electrical codes.

Specs:

- Air Inlet: Compressed Air or Gas (DO NOT USE COMBUSTIBLE GASES) Air Outlet 2″ NPT fitting. Inlet 1/2″ NPT male.

- Weight: Lightweight with a compact, ergonomic design

- Temperature: Maximum 850°C continuous. MHI controls and an accurate flow meter are recommended if used close to the maximum temperature.

- Voltage: 208/220/230/240VAC Frequency: 50/60 Hz. The picture above is the approximate unit—dimensions: 9″Diameter (at flange) and 22″ Long envelope.

- Power Consumption: ~ 10 Kilowatts Output Nominal@240V. when used as a plug-in for 208V, 220V, or 230V supply the power is slightly lower.

- Power Control: The optional control panel allows you to change the airflow or the output power, varying the output temperature.

- XPAN™ is required if power and temperature control options are required. This is shown as an option.

- Flowmeter not included. Shown as an option.

- Display – Not included- optional (HPAN and XPAN units have displays)

- The built-in Thermocouple can be linked to an external display or the control panel.

- Control panels have an ethernet socket for program upload and downloads.

For users who wish for much more precise control and /or plan to use at a lower than the maximum power, an XPAN Control Panel 208V/220V/240V is recommended. The units plug into the 208/230/240 V plug-in. The minimum flow for air is about 18 SCFM or higher and should be maintained. The unit should not exceed the maximum temperature of the device (note that the inlet maximum is considered at 60°C).

Please contact MHI at 513-772-0404 for panel quotes or use the pull-down menu above.

When operating close to the maximum rated temperature, it is advisable to use SCR-based controls with a rapid overtemperature cut-off T/C (thermocouple) and the process T/C.

When planning to use above 700C an option Y?C is recommended. Please select it in the optional menu (it is a Mandatory option as of June 2021).

For HIPAN/XPAN Control Panel information, please click here.

The picture shows a UL508A XPAN with a stand.

MHI Inc. USA

MHI Inc. USA

MHI Inc. USA

MHI Inc. USA

MHI Inc. USA

MHI Inc. USA

MHI Inc. USA

MHI Inc. USA