Hot Plates and High Heat Flux Radiators

Thermoplate™ models 1000°C (GAXP MODEL) or 1200°C (HIGHBO-GAXP MODEL), 9″x 9″. The Adjacent picture shows a TLID.

High Emissivity Ceramic Plates

Contact MHI

Special Web Prices

9″ Diagonal

9″L x 9″W (200°C-800°C)

9″L x 9″W (200°C-1000°C)

9″L x 9″W (500°C-1200°C)

18″ Diagonal

HP220-GAXP-1000 (18×18) (200°C-1000°C)

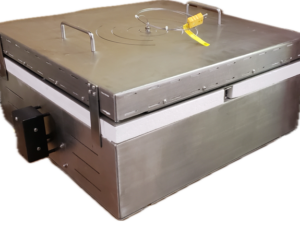

Thermotable (1400°C)

Patented Radiator Sub-Assembly for Electronics Materials Clean Furnacs and Radiators

Round 12″ 14 KW Large Disc with Orthogonal Terminals

Contact MHI

Thermotable™ 1400°C

HP220-HIBO-1400 (9×9) New* SUPERPOWER MODELS for 14 kW.

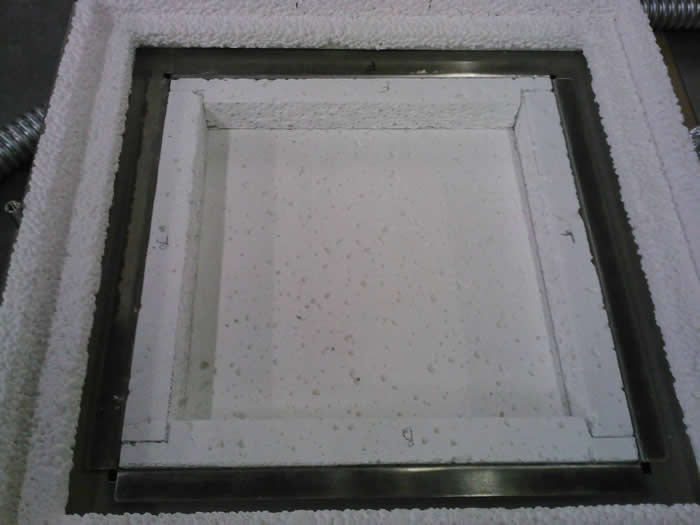

Each Thermotable™ has a high uniformity electronic temperature/power controller and transformer. The Thermotable™ is provided with a TLID. The TLID is a cover plate with a space of ~1″ between the top and inside of the TLID. The total height is almost ~22″ for a Thermotable.

Contact MHI for information on open-top high flux High heat flux over 500KW/m2 models.

MHI Thermoplates™ are an industrial grade, high power, high temperature hot plate capable of reaching temperatures of 1400°C within 4 seconds after initially reaching full power. Ideal for use as a laboratory hot plate. Thermoplates™ feature a stainless steel construction and electronic controls. Thermoplates™ are offered with quartz or ceramic tops, both exhibiting excellent uniformity.

| General Information | |||

Internal features of the Thermoplate construction include combinations of special ceramics and metals with the UltraSpiral heating element, as shown in the pictures below. There is a choice of tops (closed and open) up to 1800°C. Please contact MHI. |  Click for Ceramic Containers and Plates. Easy online purchase. TLID and thermocouple.

| ||

Complex Heating Element Provides Excellent Uniformity in Thermoplates. Years of Use. Complex Heating Element Provides Excellent Uniformity in Thermoplates. Years of Use. |  Advanced Materials and Superior Craftsmanship across the Thermal System/Device. Unparalleled engineering. |  MHI Technology in high-temperature metal-ceramic composites and thermal matching ability ensure long service life. | |

What is a TLID™? It is an insulated lid-chamber with about 1.5″ of uniform chamber space from the horizontal Plate to the TLID- roof. Chambers inside the TLID contain a thermocouple integrated with them. The lid chambers provide a canopy for large loads with exceptional temperature uniformity. The TLID chamber has an integrated guided mechanism for quick and safe lid insertion. There is no standard Lid for the Glow Panel (GP models); however, MHI can offer custom swivel closing hinged devices (like a door) for the GP models.

Contact MHI

- Usable Plate Size 9″ x 9″ Diagonal Uniformity 9.” (Plate tops and shock-resistant tops). A TLID is available.

- Usable Plate Size 18″ x 18″ Diagonal Uniformity 18.” (High-temperature shock-resistant grill tops). The TLID is available.

- 600°C, 700°C, 1000°C, 1200°C, 1400°C [Thermoplate™ and Thermotable™] with Plate.

High Heat Flux Power Radiator Only- Element temperature. The top available is up to 1700C.

Several tops may be used with a Thermoplate™ (4KW, 16KW, 50KW, or 1 MW Radiator) or with the Thermotable™ (14KW radiator).

Contact MHI for the new SuperPower ThermoTable™ models, available in 9″ x 9″, 18 “x 18″, or 36″x 36” sizes.

Each Thermoplate has a uniform electronic temperature/power controller and transformer. A picture of a Thermoplate is shown below. It is almost ~5 “high.”

– No NOx burners. Decarbonized Product.

High-Temperature HotTOP™ for heating to high temperatures from above. Click here.

Electric Hot Plates

Electric Hot Plates

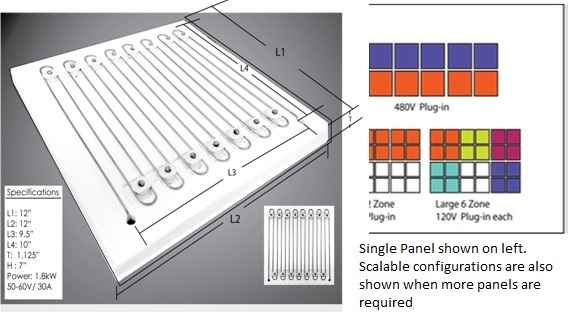

The choices are 9″x 9″, 18″x 18″, and custom plates. Standard Power and High Power. Decarbonized. Low Profile. Thermoplate™ and Thermotables™ are Hot-Plates with surface temperatures above 400°C, 600°C, 1000C, 1200C, and 1400°C (Thermotable). The TLID is available for all models.

For MW power flat radiators (2 meters x 2 meters), click here.

Uniformity

High Heat Flux Thermpoplate™ models with grill tops allow direct radiation heating depending on spacing. The several top materials may be used up to 1700°C. MHI specializes in high-temperature top materials with several features that will suit even the most demanding user.

- Thermoplate™ and High Heat Flux Themoplates/Thermotables are wide-area high-temperature products rated by temperature and surface area.

- A surface heating device’s rating is based on its power, heat flux, radiation area, type of top, and radiating temperature, which can be as high as 1850°C.

- The heating is with an optimized coverage heater.

- Custom sizes available

- Contact us.

BPAN-UL for 9″ x 9″ (typical only) models

XPAN UL with stand

- Choice of Tops for Thermoplates and High heat-flux Thermoplates and Thermotables.

- Surface heating devices offer radiator temperatures from 1300°C to 1850°C.

TRIPAN Three-phase controller for Glow Panels for 50 KW Thermoplate.

- Plate tops and high heat flux grill tops to 1700°C.

Hot Plate uniformity depends on the coverage. With the TLID (optional), the uniformity is within ±2°C on the Plate for even the 18 “x 18” models (customer report).

| Thermoplate Plate Top. 1000°C/1200°C. MHI HP220-GAXP®-1000 and 1200 Models 9″x 9″, 18″x 18″ and 36 x 36″ Unit height about 5″ | Thermoplate Models | Thermotable High Fux 9″x9″ (14KW) Unit height about 18″” |

Comparing typical Gas Burners to Electric GlowPanels™

Please compare the Power and Temperature

Power Rating Conversion

2 kW = 6,829 BTU/hr

90,000 BTU/hour = 26.4 kiloWatts (kW)

The radiation intensity increases with temperature

A faster heat-up and drying results from a higher temperature and higher power

A faster heat-up and drying results from a higher temperature and higher power

* Source: https://en.wikipedia.org/wiki/Flame. Note that the average temperature is not the peak temperature, which could be higher. MHI-patented materials are considered in the comparison. Glow panels offer non-turbulent heating. Compare the Power Density of Lasers, Sunlight, Gas Flames, and More. |

This class of GAXP™ Heater is classified as a semi-finished module, which needs to be installed only by certified electricians who are cognizant of the dangers from exposed electrical and thermal systems. Please do not hesitate to have your electrician contact MHI for questions.

Please email us or call (513) 772-0404

Thermoplate™, Thermotable™, and Glow-Panels™

Compared with other commercial Hot Plates. MHI offers a one-year warranty on heating elements/heaters on select Thermoplate™ – Hot Plate Models.

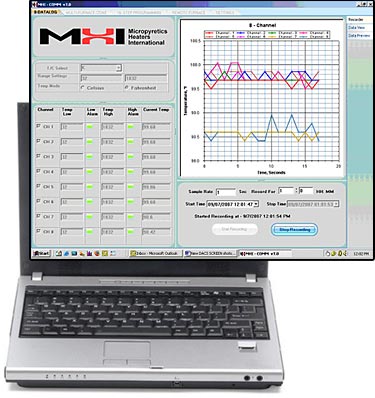

Thermoplates™ offers High Life, High Warranty, High Power, High Temperature, High Heat-up Rate, and large Hot-plate size availability. Thermoplates are similar to hot plates – used in a horizontal condition. MHI hot plate and glow, panel models are specially constructed with thermal shock-resistant materials. Most models offer the optional guided TLID chamber (t/c included in select TLID models). The temperature and power control panel provided with the Thermoplates may be used to set a precise temperature or a profile – read and control functions are included for versatile process programming. The Ethernet system for data acquisition may be used to plot, save or download the data, i.e., remote monitoring capabilities.

Oxygen Sensor in Thermoplate™ [Inside the TLID]

Thermoplate™ 600°C, 800°C, and 1000°C

- High Emissivity Ceramic Plates

PLATE MODELS

Best uniformity is obtained with the TLID option

Multi-panel plates.

Versatile Thermoplate™ Programmable Control Panels

Usable Plate Size 9″ x 9″ Diagonal Uniformity 9.”

Usable Plate Size 18″ x 18″ Diagonal Uniformity 18″

600°C, 700°C, 1000°C, 1200°C, 1400°C [Thermoplate™ and Thermotable™] with Plate.

1700°C-1800°C [High Heat Flux Power Radiator Only]- the temperature is element temperature. The grill top available is up to 1700C.

A grill top may be used with a Thermoplate™ (4KW Radiator) or a Thermotable™ (14KW radiator).

Contact MHI for the new SuperPower ThermoTable™ Models.

More Surface Heating Devices

HOT-TOPS™ and Glow Panels for Top Heating, Bottom Heating, and Vertical Heating Configurations

(please click on the picture for details)

MHI offers a variety of specialized surface and radiative electric heaters with industry-leading controls.

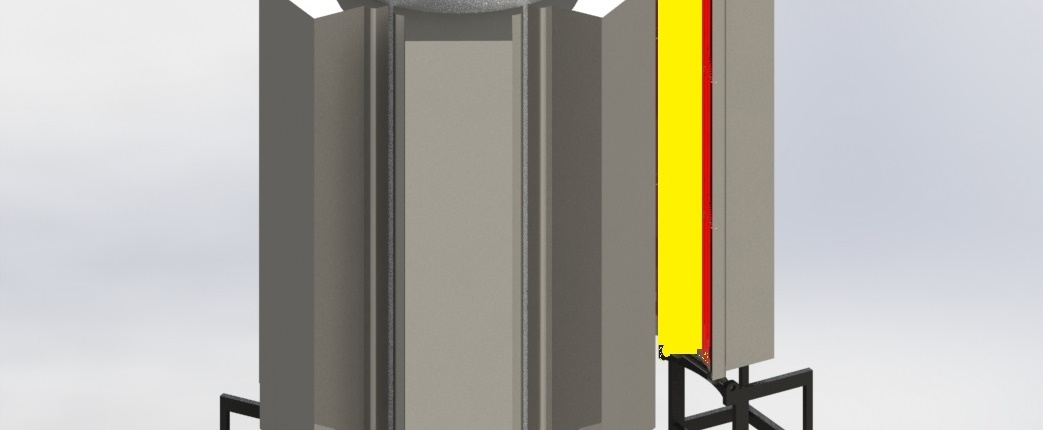

Giant Vertical GlowPanel™

Heated Glow Panel (GP)

High Power Density (kW/m2)

Industrial GlowPanel™

Special Industrial Use

New GiantHeat™

Industrial Thermoplate™ 30″ x 30″

Heat Flux is 55 W/square inch. Very powerful.

Facets for up to 2 MW.

With incredibly high power output per unit area and very high temperatures.

Please review the Heat-flux calculator.

Custom Radiative Vertical Wall. Glow Panel or Thermoplate

18″ x 20″ Model shown

Model: GP(W)-24 (24 kW)

New- Please contact MHI for GiantHeat™ Panels- use in the oil industrial sectors. Window type with stand. View Models. ~ 4 – 150 kW

High power density ~up to 150W/sq.in or ~22 W/sq.cm over the large surface.

Combine with efficient Airtorch® for best electric drying.

Patented. Up to 1900°C depends on model.

Custom. Please review Heat-flux calculator.

Industrial Hot Top Radiators

Hot-Tops. Patented. ~ 6 kW. View Model Details.

HotTops may be controlled over a wide power and temperature range.

BPAN-O-PLUS Control Panel

BPAN-O-PLUS Control Panel