The Most Modern Electric Steam Generator and Boiler Technology.

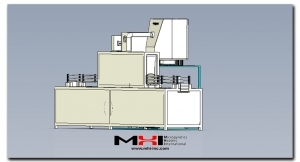

The units offer independent control of temperature, pressure, flow rate, and steam output triggers—ethernet and HMI touchscreen inputs. The PLC operation can directly control humidity or respond to a process variable. From a few kg/hr to tons per hour of steam.

Click here for the Steam Products Home Page.

Typical models. Please specify your flow, temperature, and back pressure requirements. The flow and temperature are variable and can be set on the touchscreen HMI.

- GOAB-Var-8KW-240V-500C-40(PV) 2- 5 Kg/hr 500C, 40 Bar. Single phase.

- GOAB-Var-10KW-240V-800C-4(PV) 2- 5 Kg/hr 800C, 4 Bar. Single phase.

- GOAB-Var-12KW-240V-500C-25(PV) 6- 12 Kg/hr 500C, 25 Bar. Single phase.

- GOAB-Var-15KW-240V-800C-25(PV) 6- 11 Kg/hr 800C, 25 Bar. Single phase.

- GOAB- (2-5)kg/hr GOAB-Var-9KW-240V-1000C-10(PV) 2- 5 Kg/hr 1000C, Up to Bar. Single phase

- GOAB-Var-24KW-240V-500C-10(PV) 10-25 Kg/hr 500C, 10 Bar. Three phases.

- GOAB-Var-30KW-480V-300C-4(PV) 8-25 Kg/hr 300C, 4 Bar. Three phases.

- GOAB-Var-30KW-480V-800C-2(PV) 12-24 Kg/hr 800C, 2 Bar. Three phases.

- Click here for high-flow rate OAB models for steam flow higher than 60 Kg/hr.

Pressure and flow rate are independent settings. The flow rate can vary from about 30% to the total amount of the specific model—modern HMI panels for touch screen interface for operator ease. The control panel can be UL or with cUL ratings. ASME PV ratings are provided when requested.

For high-flow rate models 60-2000Kg/hr, please click here

GOAB™, when the back pressure expected, is more than 2Barg. MOAB™ when it is less. Please specify in the RFQ.

From 2 Kg/hr to 24 Kg/hr Scalable Super-heated Steam with variable flow and back pressure.

For 1 Kg/hr, models to 1300C, please click here

For 60-2000Kg/hr, please click here

Control the flow and temperature independently with flow and power controllers—Independent pressure control.

-

GOAB – Scalable Platform Models/Features. Set flow on a touch screen HMI. Set the flow temperature and pressure independently.

-

More MHI team Generator Models, Plasma Steam Models, and Steam Chambers.

- The OAB® steam generator systems will change your thoughts on super-heated steam regarding installation, safety, size, fuel production, and operational costs.

- Please contact MHI for details, information requests, or quotes.

Easy to use.

On-off steam. On or off for any steam-gas mix.

For fine-tuning pilot process development for quick scale-up to production. High-Temperature Steam for Pharma Use.

Versatile instant steam generator with independent control of temperature, flow, and pressure functions.

Q: Are your Panels UL, cUL, or CE-rated? CE rating is only of limited availability.

A: Yes, one can order with any of these ratings.

XPAN GHGA XPAN

XPAN GAGA

Q: What are your typical pressure vessel standards?

A: Please contact MHI. Our usual standards are ASME Section VIII Div I.

UL-rated Panels.

Visit this page for:

- Decarbonized high-efficiency, on-demand, high-temperature steam or steam-gas mix generators.

- You are looking for independent control over temperature, flow rate, and pressure

- You are considering changing from a large combustion boiler to a clean steam generator, including discrete generators for every station

- If you are planning new fuel and CO2 conversion or related technologies

- if you have to optimize steam chemical reactions for syngas.

- When dedicated to sustainability and efficiency with steam generators.

- If you prefer to decouple pressure and temperature in your steam output.

- Steam is critical for high temperatures, say 400°C, 800°C, or 1300°C.

Typical and frequently asked questions:

Q: I need a variable steam rate generator at a maximum temperature of 400°C to 800°C. Can I use your steam generator GOAB models? Ans: The GOAB models are the correct choice for variable flow and temperature requests. The price will also depend on the pressure vessel rating and variable (adjustable) range of steam flow. Typically we are asked for 3-6 Kg variable or 4-12 Kg variable steam at the high temperature with unit-adjustable backpressure.

Q: Can you provide a shell of 40 Bars? Ans: We can provide ASME Section V111, Div 1 standards with external rating.

Q: Can I get a touchscreen HMI control panel? A: Yes, this is our standard on some models.

Q: I have a 49 KW boiler. Can I use your steam generator instead? Ans: Yes: The closest fit is the GHGA-36-(PV) or the OAb-50. Unlike boilers, the steam generator units can be on-off at will. No idling is required. The temperature output of the steam will be between 130C and 800C depending on the model, flow settings, and power settings. The price will depend on the pressure required and other selected features.

Q: Do steam generators work differently than boilers? Ans. Yes, steam generators work differently compared to pressure boilers (1) they are instant on-off, with no idling required (2) in a clever way, the pressure will only build to the maximum line requirement to improve the efficiency (3) temperatures can be set for very high temperature with high-quality dry steam, and (4) they can be easily matched to other line or cross-line pressure flows. Saves energy. Adds to the world sustainability index. Allows for new reactions and higher productivity options to be explored.

Q: I have a 200 Bar steam line that feeds the entire industrial testing plant. Can I use discrete 40 Bar steam GOAB units from you? Ans: Yes, the savings are enormous, and chances are that you will also be converting from a coal, oil, or gas-fired boiler to a clean electric unit. Use units at discrete locations—no dangerously long piping at high pressure and no idling—On-off at will.

Q: Antimicrobial steam? Yes, please contact MHI for data on antimicrobial or sterilization quality steam. Visit the Steam application page.

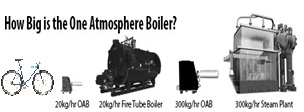

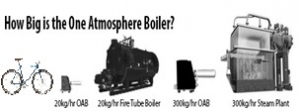

The steam generator footprint is likely considerably lower than a traditional boiler with the same output steam.

Instant high-quality high temperature and large amount of steam output

Packing Standards follow International Norms

Are you considering biofuels or valuable products like methanol from CO2 conversion? Please contact MHI Inc. with your reactor requirements.

Very accurate high temperature steam is required for pharma. Please select the GHGA models.

MHI provides the most efficient steam delivery flexible tubes.

High Temperature Steam Extender Tubes

Pharma bottle rapid sterility level cleaning.

Process has to be correctly adjusted for time and temperature

Want to find out how MHI can help you meet your steam needs?

Please fill out a quick questionnaire by clicking on the product of interest.

We will help find a good solution to meet your needs.