Description

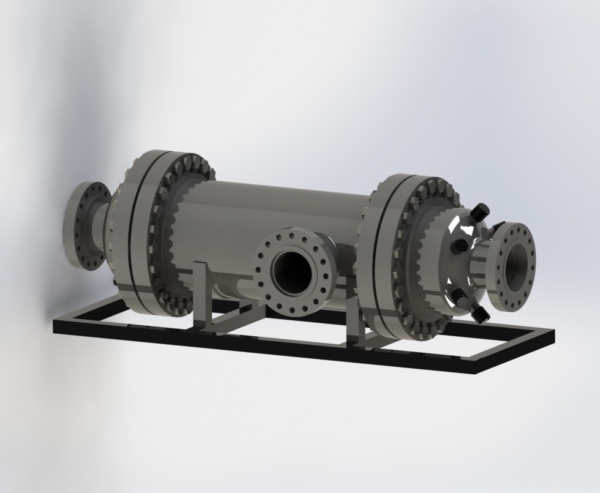

Special” High Temperature Industrial Airtorch® with input up to 300°C and Output up to 700°C.

This unit has high power capability ~42KW. 240V 3 Phase. 50/60Hz. Heavy-Robust Engineering. Great Warranty.

6 Bar Vessel. Flanged.

TRIPAN Controller. Please specify CE, UL or cUL and plant voltage.

More GTA Models. Click Here.

Please contact MHI for assistance by clicking here.

For Main GTA Airtorch® Home Page

The Airtorch® is a highly scalable electric process air heater typically utilized as shown in the Airtorch® Infographic. The typical Airtorch model output is up to 1200°C (~2150°F). They offer high flexibility and greater control of your process heaters – room temperature is assumed as 25°C for standard input – HI models allow even a 600°C input . Several models available in each class. Simple 5-step selection guide and flow as a function of temperature for various models. MHI provides models for 750°C, 925°C, 1000°C, 1100°C and 1200°C.

Why MHI Airtorch®? Very low pressure-drop, highest-temperatures, high-efficiency, industry leading quality, price and delivery. Recuperater requirement? – Please consider the Airtorch® for efficiency and low pressure drop- note that pressure drops in standard heat exchangers may cost the user a lot of wasted expenditure for forcing the air. See examples here.

MHI Airtorch® uses: Industrial Equipment, Lab and Analytical Equipment Medical Equipment, Combustion Simulation (simulate), Military and Defense, Rubber and Plastics, Pharmaceutical, Pharmaceutical Equipment, Transportation, Water and Waste Water, Commercial, Adhesive Activation, Food Service Process Heat, Chemical Reactions, Laboratory, de-soldering Heat Staking, Melting, Energy Processes, Climate safe benefit, Energy, Soldering, Welding- Brazing, Weld preheat, Semiconductor, Medical, Preheating Gasses High speed heat shrink, Curing adhesives, Hot Air Processor, Powder drying and high temperature high velocity regime, Automotive, Packaging & Sterilization, Paper/Printing, Bio-Fuels, Digestion, Semiconductor processing, Soldering/Brazing, Textiles, Semiconductor, Energy Processes, Nuclear, Bio, Diesel, Process heater, gas heater, powder, gas pre-heater, air-pre-heater, supplemental heater and many other process heating applications. Flow simulation whether combustion or high temperature viscous. wafer processing, metal finishing, Solvent drying, steam and air hybrid process heaters, Flow Air Heating, preheating, Hot Air Processor, Shrink Fitting, Synthetic Fabric Sewing. Pressure vessel, simulate, Baking, Laminating, Metal Working, Packaging, Plastic Welding, Sealing, Soldering and brazing, In-line heaters, Compact heaters, Parts cleaning, Biomass extraction , Bio- reclamation, Photo-resist material, Semiconductor processing equipment, Supercritical fluid heating, Solvent replacement, Test beds, Life Sciences, Air, Steam, sCO2, Photovoltaic, Semiconductor processing, Curing and Drying, Electronics, Efficient Heat Shrinking, Thermoforming/Sealing […]

MHI Inc. USA

MHI Inc. USA

MHI Inc. USA

MHI Inc. USA

MHI Inc. USA

MHI Inc. USA MHI Inc. USA

MHI Inc. USA