Box Furnace M-Series

Now offering 1-year warranty on heating elements for select standard furnaces. Please contact MHI.

Box furnaces require inside and outside stainless steel of the correct thickness to prevent distortion. MHI offers best in class roof hanger, proper cooling of external surfaces, and FiberFree™ refractories with the swing-away balanced safety door feature. MHI M-Series Box Furnaces (including the LTF series) features our largest internal dimensions for box and muffle furnaces. This, combined with high operating temperatures and the incredible warranty, makes the M-Series a great choice for many users.

Easy access features make installing and maintenance very easy. Carefully thought out designs that prevent distortion and maintain roof stability with roof hangers.

M Series Furnace Models | ||

|---|---|---|

| Model Number | Temperature | Chamber Size |

| M18-40 | Up to 1760°C (1800°C/3272°F Max) | 12″H x 12″W x 16″D |

| M14 | Up to 1400°C | 12″H x 12″W x 16″D |

LTF Class

Much Larger Box or Front Loading Furnaces THF, LTF Class

| Model Number | Temperature | Interior Dimensions |

| LTF2-(11-17) | 1100°C – 1700°C (2012°F – 3092°F) | 16″H x 24″W x 24″D |

| LTF2-14 | 1400°C (2552°F Max) | 16″H x 24″W x 24″D |

| THF-1400-6- GAXP | 1400°C (2552°F Max) | 24″H x 24″W x 24″D |

| THF-1400-12- GAXP | 1400°C (2552°F Max) | 12 Cubic Foot Furnace |

Box and Muffle Furnace Models

All MHI box and muffle furnaces feature rugged stainless steel construction, electronic controls, and MHI’s highly acclaimed heating elements. Our furnaces have maximum operating temperatures of 1800°C and continuous operating temperatures of up to 1760°C. See the tables below to determine which model best suits your application.

| Model Number | Temperature | Chamber Size (usable space may be lower) |

| M14-GAXP | 1400°C ( 2500°F) | 12″H x 12″W x 16″D |

| M18-40 | Up to 1760°C (1800°C/3272°F Max) | 12″H x 12″W x 16″D |

| Z18-40 | Up to 1760°C (1800°C/3272°F Max) | 6″H x 5″W x 6″D |

| H14-GAXP | 1400°C (2500°F) | 8″H x 7″W x 8″D |

| H18-40 | Up to 1760°C (1800°C/3272°F Max) | 8″H x 7″W x 8″D |

| N18-40 | Up to 1760°C (1800°C/3272°F Max) | 12″H x 12″W x 13″D |

| LTF2-1400 | 1400°C | |

Furnace Applications

MHI’s high performing furnaces are built to endure the use and abuse of many different applications. Our furnaces have seen use in small scale laboratory environments all the way to industrial production facilities. Contact Us to see which furnace is best for your application.

| M-Series Suggested Uses | |

| Industrial Furnace | Metal Melting Furnace |

| Heat Treating Aluminum | Heat Treatment Furnace |

| Melting Furnace | Heat Treating Furnace |

| Sintering Furnace | Melting Aluminum |

| Debinding Furnace | Annealing Furnace |

| Tempering Furnace | High Temperature Oven |

Furnace Accessories

MHI now offers a variety of accessories to be used with our furnaces. Common accessories are clips, braided wire, hangers and other useful tools. To view these accessories, visit MHI Element Accessories or our MHI store.

Other MHI Products

Superheated Steam Generators|Microheaters | Airtorch®| Heating Elements | Radiative and Convective Heating Augmentation Heating Panels| Furnace and Furnace Accessories | Thermoplate| Microheater | Robust Radiator™ | Fiber Heater | Silicon Carbide Elements | Plasma |Nano Products | Electric Control Panels

Box & Muffle Furnace Features

For Gas or vacuum and other sensors please click here. These options are routinely shown on the quotations.

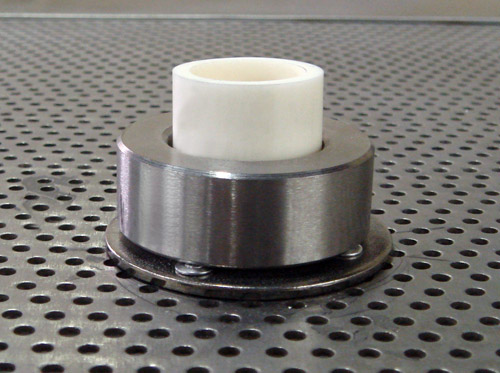

Chimney Exhaust Port

The chimney exhaust port is a standard MHI furnace option.

The ceramic tube is made out of NanoFractalAlumina™ with high thermal shock resistance.

Optional chimney exhaust port and other gas/steam featur or vacuum feature shown with standard perforated furnace top.

| M, N, H and Z Series Feature GAXP or Molysidide heating elements |

| Safety 3-arm horizontal swivel door keeps the hot face away from the user. |

| Non-Sag NanoFracralAlunina™ Roof Holders allow for large spans. |

| Plug & Play operation. High Insulation. High Energy Efficiency. |

| Stainless steel construction. Thickest gauge used in the industry. |

| Forced air fan cooling. Double wall construction. |

| 3 layers of refractory. FiberFree™. High Safety. |

| Easy-open twist latch. |

| Manufacturer warranty. |

| Box design keeps exterior surface temperature 50°C or less. |

| Purge gas option available. |

Useful Information

What kind of uniformity do MHI furnaces offer? , What kind of energy efficiency do MHI furnaces offer?, M-Series Box Furnaces feature Molybdenum DiSilicide heating elements.

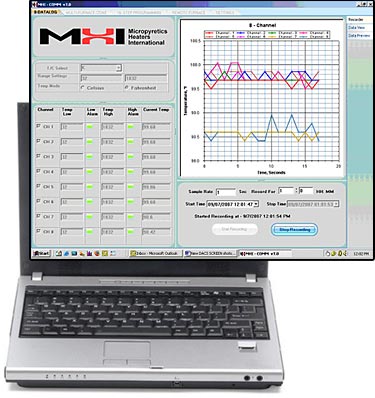

Furnace Controls

MHI offers electronic controllers with features such as overtemperature controls and programmable steps. In addition to standard electronic controls, MHI DACS allows for remote furnace locations, data logging and intricate step programming.

| MHI Furnace Controls | |

| Many of MHI’s electronic furnace controllers feature multiple voltage inputs, overtemperature controls, programmable cycles and a number of other features. For more information about MHI’s control panels, Contact Us or See More Information. UL508A control panels |  HIPAN Control Panel |

| MHI Data Acquisition and Control Software (MHI DACS) | |

| MHI Tube Furnaces are compatible with MHI DACS for furnace controls, step programming, data logging and more. DACS also allows for remote furnace control, allowing one central location to control multiple devices. |  MHI DACS Software |

Furnace Summary

MHI has pioneered several specialty furnaces. Standard furnaces are listed above. Many can be customized to the requirements of the user. Please click on a category below. Please also contact MHI if seeking to upgrade an old furnace with the modern GAXP® heating elements or fiberfree™ insulation. Rapid cooled sealed furnaces for Austempering and Martempering or similar heat treat conditions with accurate hold temperatures. Industries served include the industrial, heat treat, medical, commercial, R&D, innovation, packaging, instrumentation, aviation, transportation, refrigeration/air conditioning, ashing organic and inorganic samples, petroleum refining, gravimetric analysis, biomass, chemicals, forest products, iron and steel, food and beverage,cement, glass, fabricated metals, plastics and rubber products, reactors, alumina, aluminum, transportation equipment, foundries, computers, electronics, and electrical equipment, textiles, machinery, and all types of critical manufacturing.

|  |

Guide for furnace selection

| Lab Scale Furnaces | Industrial Scale Furnaces | Steam Ovens | Control Panels |

| Box Furnaces Bottom Loading Vertical Furnaces Horizontal Tube Furnace Tensile Testing Compact Slider Stackable Modules | Bottom Loading Tube Furnace Horizontal Tube Furnace Top Hat Furnaces Hybrid Furnaces Front Loading PC Concentrator Zapper | Recirculating Ovens Continuous Oven Custom Convective Ovens | Single Phase SCR’s 3 Phase SCR’s Electric Controllers Data Acquisition System MHI-8DATALOG Simple Gas Mixing System (automated) |

| Now Offering 1 Year Warranty on Heating Elements for Certain Classes of MHI Furnaces. Please contact MHI for full details. For easy purchase of spare parts visit our store – (spare parts) | |||