DPF, MPDNA, and GPDF Airtorch Process Heaters and Air Preheaters to 1200C

GDPF Airtorch® Process Heaters & Air Preheaters-Pressure Vessel.

For MW and large flow electric process gas heaters, please click here.

| Temperature | Lower Power (1-45KW) | High Power 60-500KW 500kW to 15,000KW |

| 200-900°C | LTA, VTA, MTA925 | MVTA/MTA |

| 900-1000°C 1000-1100°C | MVTA-900-(DNA) Models | MVTA/MTA |

| 1200°C | MPDNA VTA-MPDNA and GDPF-MPDNA GDPF-SH | 1200°C+ |

| High-Pressure Enclosures (GTA, GVTA) | Up to 1200°C |

| Resources |

DPF Models Request Information

DPF Models (2200°F) – NEW! (Click the Link for Model Numbers) (previously AT models) | Controls | Accessories | |

DPF Airtorch™

| Applications:

Power Cycle Use | ||

Maximum Temperature | Key Selection Feature | Typical Power Range | |

General Specifications: | 2200°F | Highest Temperatures Please Contact MHI For Flow Rate-Temperature Diagram. | 3 to 15 kW units for single phase |

Airtorch™ System

4 kW DPF Airtorch® and 15 kW DPF [Single Phase]180- 360 kW and larger for three-phase electric.GDPF-MPDNA 6.5 KW~1200°C

Special nitride refractories and insulation in MPDNA models |

|

4 kW DPF Airtorch™ The fan model (V-DPF) is shown. Available with Blower and Compressed Air Input. LFC (Low Flow Safety Cut-off) is included. | ||

| 6.5 kW DPF Airtorch™ | The picture shows DPF220MP-6 with fan or low-flow safety control attachments. Needs an MHI control panel for low-flow control activation. All DPF models feature high efficiencies, easy integration into existing systems, and low emissions. Use MHI Airtorch™ to improve your process. Save money. Easy Selection Criteria. One graph captures SCFM per kW. DPF Airtorch™ Benefits Highly Efficient: Saves energy and time while improving your process heating. | |

For more information, including flow rate tables or detailed specifications, Contact Us Now.

DPF Airtorch™ Suggested Applications.

Airtorch Use Sectors

Flow simulation, whether combustion or high temperature, is viscous. Industrial Equipment, Lab and Analytical Equipment, Medical Equipment, Combustion simulation Military and Defense, Pharmaceutical, Rubber and Plastics, Transportation, Water & Waste Water, Commercial, Melting, Adhesive Activation, de-soldering, Heat staking, Food Service, Process Heat, Accelerating Chemical Reactions, Laboratory, Transportation, Defense & Aerospace, Energy, Medical, Preheating process gases, High-speed heat shrink installations, Pharmaceuticals, Curing adhesives, Hot Air Processor, Powder drying and high-temperature high-velocity regime, Automotive, Packaging & Sterilization, Paper/Printing, BioFuels, Soldering/Brazing, Textiles, Semiconductor, Energy Processes, Nuclear, Diesel, Process heater, gas heater, gas-pre heater, air-pre heater, supplemental heater, and many other process heating applications. Testbeds, Life Sciences, Photovoltaic, Semiconductor processing, Curing & Drying, Electronics, Heat Shrinking, Thermoforming/Sealing […]

| DPF Airtorch™ Suggested Applications | |

| Sintering, Oxidation. Sensors testing. | Debonding for Paint |

| Drying | Fusing when within a temperature range |

| Curing | Hot Gas/Steam Heating, for example, for glass |

| Heat Treating by itself or as a furnace enhancer | Joining |

| Gas Preheating for Heavy Engineering, simulation | Air Preheating for multiple energy efficiency solutions |

| Process Heating, Stands, Air Combustion Simulation | Brazing, Rapid Heating |

Airtorch™ System Introduction and Flow Charts. Use for continuous VOC removal or use for rapid heat treatment and surface treatments like finishing to hardfacing. The operating cost estimate per pound of VOC removed is about ~0.5¢*for regular ppm contamination concentration removal. Compared with over $4/lb. Please contact MHI to verify the calculations.

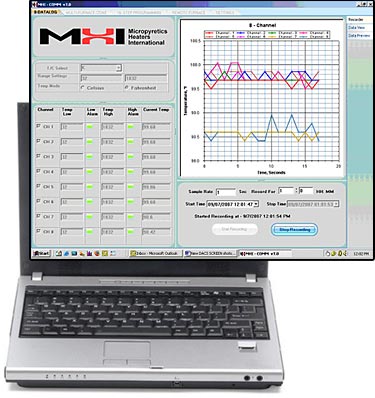

Electronic Controls

MHI’s DPF Airtorches™ are compatible with our electronic control panels and DACS software. Standard features include overtemperature controls and programmable steps. In addition to standard electronic controls, MHI DACS allows for remote furnace monitoring, data logging, and intricate step programming.

| MHI Airtorch™ Controls | |

| Many of MHI’s electronic furnace controllers feature multiple voltage inputs, overtemperature controls, programmable cycles, and several other features. Contact Us or See More Information for more information about MHI’s control panels. |  XPAN (Several Configurations) |

| MHI Data Acquisition and Control Software (MHI DACS) | |

| MHI devices are compatible with MHI DACS for furnace controls, step programming, data logging, and more. DACS also allows for remote furnace control, allowing one central location to control multiple devices. We are now offering DACS – Ver. 8.1 on select Panels – standard. |  MHI DACS Software |

Accessories

Airtorch™ Heater Accessories | |||||||||

| NPT Nozzle with fitting for pipe extension | |||||||||

| FS750-A – Adjustable flow rate detection valve and switch | |||||||||

| New | FS750 – Flow rate detection valve and switch | ||||||||

| FLM750 – Flowmeter 2-23 SCFM (click for larger images) | ||||||||

| FTB750-6 – 6′ Air/gas supply tubing | ||||||||

| MTAR – Moisture trap ensures dry air to AirtorchTM | ||||||||

| FANCS – Fan control (typical) for DPF or AirtorchTM | |||||||||

| FAN – Fan (typical) for DPF or AirtorchTM | ||||||||