High Flow Rate, High Power, and High Temperature Electric Process Gas Heaters

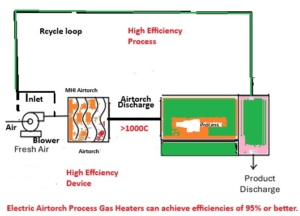

MHI Electric Airtorch® products are compact and energy efficient.

- Save on operating costs over traditional electric or gas heating.

- Click to learn about decarbonization and energy efficiency.

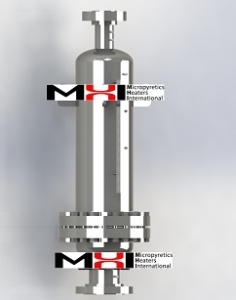

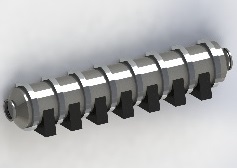

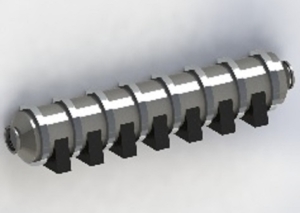

- Save on space, e.g., a 15 MW is only about 6 m long, or a 48 MW could be only 9 m long

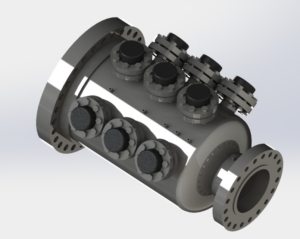

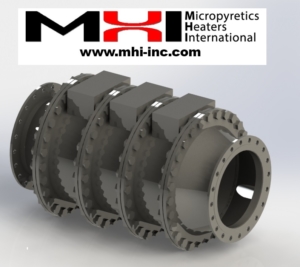

- New MHI Array heaters for 50 MW and above.

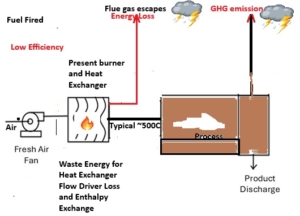

- Electric devices are often more efficient than fossil fuel-fired heat exchangers (compare a 4 MW substitution for a 16 MW fossil fuel system that operates at a very high efficiency).

- Designed for safe electric voltages even for large MW applications.

1 kWh of electric heating saves almost ~ (0.42 – 0.69 kg) of CO2 equivalent emissions per hour. (source).

This is important for decarbonization to assist climate change and reduce global warming.

MHI Airtorch® units offer:

- 100 kW to 140 MW compact units.

- Energy Efficient. Contact us.

- Heavy-duty use with very low-pressure drop.

- Outlet to 1200°C and above. However, the prices rise with temperature, e.g., 1200°C Airtorch® models are higher priced than 1000°C Airtorch® models.

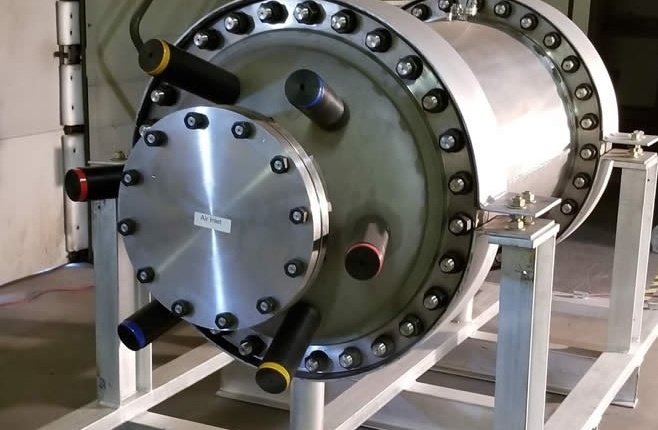

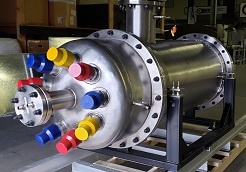

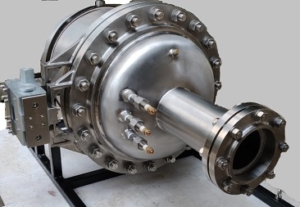

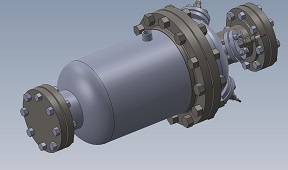

- High-pressure enclosures when required. High-pressure Airtorch® model information.

- Compare energy efficiency and cost against fossil fuel systems.

- Ratings ASME, CRN, cUL, ATEX, UL, and CE as requested.

- Ask about MHI’s communications features. Touch Screen HMI and PLC controls.

- Video(download)

- And more important features for long life…..(please read below).

MHI Airtorch® 3 Phase Systems: These systems range from 30KW to 200MW. Modern electronics allow easy adjustment of power, flow rate, and temperature. Specify the exit temperature, vessel pressure, and flow.

- Electrical heating systems are generally 2X or more energy efficient throughout the process comparison. Therefore, if energy efficiency is the aim, electricity should always be used.

- For payback goals, both the initial cost additions of a higher-efficiency product and the better returns from it must be considered.

- A trial project could have a fixed budget, forcing one to choose a lower-priced, lower-efficiency system. However, the objective is not to prove the process’s efficiency but to show project efficacy. Regardless, it can be done with high-efficiency electrical segment sections to prove trials because the climate costs are rising yearly.

- The payback period decreases dramatically if climate costs are considered. The emission price of about $283/ton of CO2 emitted by burning fossil fuels can be used for climate projects. Based on PNAS in 2024, Emissions Saved by Converting to Electrical Heaters: (4.17-6.99) × 10-4 metric tons of CO2/kWh (source).

- A higher temperature significantly adds to the production rate. More examples are on https://mhi-inc.com/decarbonization-project-costing-analysis-energy-efficiency/ (bottom of the page)

- This is the link for the cost of making CO2.

- Low-Pressure Drop

- Up to 100s of MW

- High Turn Down Ratio

- Energy and Cost Savings

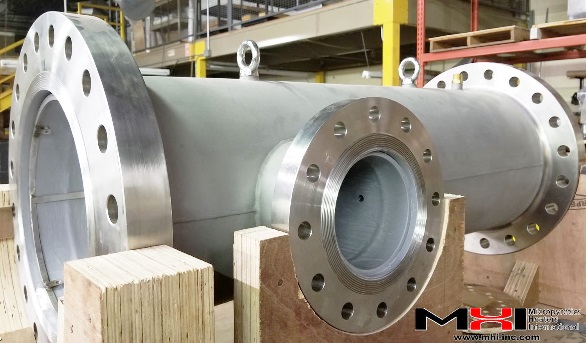

- High uniformity. Sealed. Flanges and mating flanges are provided as described.

- Continuously adjustable airflow and temperature with a flow valve and MHI power controller.

- Adjustable air temperatures from ambient when ordered to 1100°C. (Airflow temperature)

- Several safety features. Multiple thermocouple locations.

- Insulated, air/gas-cooled. Reduces flange stresses.

- PID controls and the choice of TRIPAN or I-TRIPAN controls. PLC, and HMI.

- New* MVTA (THN) advanced systems from 1MW to 200 MW and several in between. Beat all prices and compare performance.

- (HI and SH) models allow even a 600°C input. 1200°C Output.

- Extremely low-pressure drop.

- New compact Array models for 100MW and beyond with very low-pressure drops.

- The pressure drop is low. For more information and specifications, please get in touch with MHI.

- MHI offers DirectFlow™ Airtorch® models. MHI uses its combined thermal knowledge from over 30 years across diverse equipment offerings to provide low-friction flows.

- The Airtorch is used for industrial flow heating, comfort control, simulation, rapid drying ceramics, beneficiation, metal production, ore roasting and drying, high-temperature flow-induced chemical thermodynamics, testbeds, food and beverage production, pharmaceutical manufacturing and quality assurance, precious metals reclamation, pollution control applications, and efficient drying. It is also used in drying, mineral ore, cement, packaging, fuel, and other applications.

- The Airtorch® is a SmartEnergy™ device because of its energy efficiency.

- Choice of the supply voltage. 50/60Hz. Inlet temperatures can be high on specific models.

- MHI control panels handle all voltages: 220V, 240V, 380V, 440V, 480V, and 600V.

- High Pressure in-line, please click here. For more information and specifications, please contact us.

- High-Temperature Inlet Models. Exit to 1200°C (2192°F)

- Properly multi-flanged.

- Airtorch® process heating methods are quiet.

- GTA™ Models, 3 Bar, 8 Bar, 21 Bar, 60 Bar,

- High Energy efficiency – decarbonized.

Why choose the MHI Electric Airtorch®? Efficiency, High-Temperature, Robust construction materials, safety, and attractive life-cycle payback calculations.

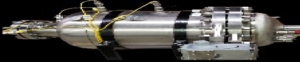

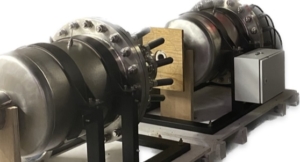

Low operational cost from the very low-pressure drop (~0.1 psig, and much lower for Duct Heaters), noise-free, quick-start, high-temperature capable – implies longer life at lower temperatures than process gas heaters that cannot reach high temperatures. Several models are in stock – all quality-engineered and carefully manufactured—and have decades of electrical heating experience. The high-power patented three-phase Airtorch® configuration yields high-temperature convective air and may be used for various applications. It is used for surface heat treatment, simulation, combustion tests, reaction engineering for carbon and calcium, cement, forestry, steel, ammonia industry use, and Other environmental decarbonization uses like preheating, drying, powder sintering, testbeds, channel heaters, and large and continuous ovens. MHI Airtorch® systems are extremely energy efficient. Stainless steel or other flanged sealed systems provide energy efficiency, temperature capability, and conservation.

Contact MHI – Typical Applications

Decarbonization: Heavy Duty Equipment

MHI is committed to sustainability.

Low Overall Energy Efficiency

Models (up to 1100C) | Power Highest Powers Units | Maximum Temperature (Highest Temperatures) | Voltage, 3 Phase All Line Voltages 50/60Hz |

|

Robust Design | 800°C/900°C/ Custom MVTA models up to 1300°C/1832°F For higher temperature Models, please click on DPF For Inline Pressure Situations, please specify the pressure

|  208/220/ 208/220/240/380/400/415/ 440/480/600 Volts 50/60HZ |

| Temperature | Lower Power (1-12 kW) | High Power (36 KW-15MW) |

| 600-900°C | LTA, VTA, MTA925 | MVTA-900-(DNA) Models, SH |

| 900-1000°C or 1000-1100°C | MVTA-900-(DNA) Models | MVTA-1000-(DNA) ModelsMVTA-DPF(DNA) Models, SH |

| 1200°C/1300°C | MPDNA VTA-MPDNA and GDPF-MPDNA | 1200°C |

| High-Pressure Enclosures (GTA, GVTA) | Up to 1200°C |

|  |  |

|  | |

| V-DPF | |

Large Flow GTA

*Unit Life and Safety: MVTA units forgive temperature exposures beyond their rated capacity, even up to 100°C for many models. Even for the 1000°C models. Calculate 3-phase Electric Power.

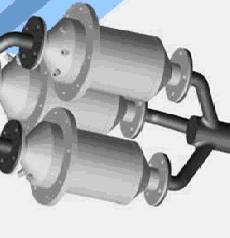

Cluster Models and High Volume Models with High Temperature Inlet

High Pressure and High Temperature: greater than 800C up to 1200C units GVTA or GTA models

please click here.

*For high kW in both the GTA and MVTA Airtorch class, please note that MHI provides a 1-year warranty and no-cost of heating element change for 1 year. Double flanged units.

ASME-flange specifications. Please contact MHI.

Contact MHI for your specific energy savings

Patented Products up to 1200C

MVTA model for 48 or 96 kW (1000°C).