Process Hot Air Heaters for Industrial Applications

MHI manufactures a comprehensive line of process heating tools from low to very high temperatures of 1500°C (~2700°F). MHI Airtorches™ are Patented. |

Overview:

|

Models:

For help choosing the right Airtorch® for your application, click here for Selection Guide.

New Variable inlet temperatures to 800°C and recirculators for energy efficiency.

Models (1200°C) (new higher temperature ) controls required | accessories | ||

Click for detailed application pageApplications:

| |||

Maximum Temperature | Key Selection Feature | Typical Power Range | |

General specifications: | 1200°C | In-line or Fan | 0.5 to 60 kW |

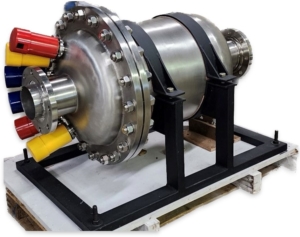

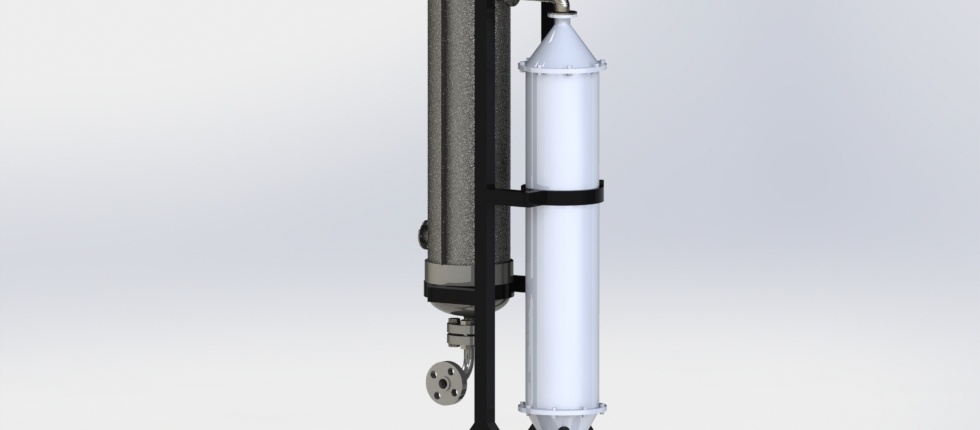

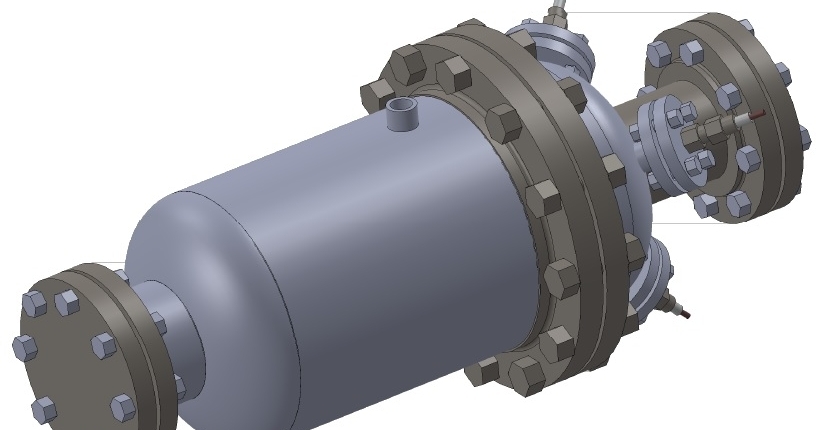

High Pressure Models GTA (1200°C) Models controls required | accessories | ||

Copyright MHI Inc. USA

| Application:

| ||

Maximum Temperature | Key Selection Feature | Typical Power Range | |

General specifications: | 850-1200°C | Pressure Vessel Model | 6 to 400kW |

| accessories | |||

Application:

| |||

Maximum Temperature | Key Selection Feature | Typical Power Range | |

General specifications: | LTA1000C | In-line | 1 to 60kW |

| VTA900C | Fan | 1 to 6kW | |

�

MTA925-(kW) NEW! (For Hydrogen and combustible gas heating) | accessories | ||

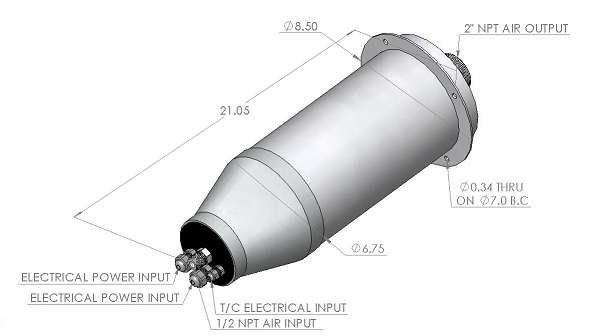

12 KW three phase or Single Phase GTA925-12 | Features and Application:

| ||

Maximum Temperature | Key Selection Feature | Typical Power Range | |

General specifications: | 1000C (1700F) | In-line only | Email MHI for models |

| accessories | |||

Application:

| |||

| Maximum Temperature | Key Selection Feature | Typical Power Range | |

General specifications: | Link | Plasma | Link |

| accessories | |||

Application:

| |||

| Maximum Temperature | Key Selection Feature | Typical Power Range | |

General specifications: | Please Call | In-line | Call MHI |

| Recirculating Airtorch Airtorch Handbook Airtorch Applications Knife Edge Die Heating | Controls Thermoplate Furnaces Continuous Ovens Pricing FAQ’s | GAS MANAGEMENT SYSTEMS: |

The latest application of the Airtorch™ is in Fluidized Beds! Please call MHI for details.

Airtorch® Applications

| Aluminum Brazing | Scorching/Burn off/Curing |

The Airtorch® has opened up new possibilities in brazing and joining technologies. Whereas in the past brazing furnaces were cumbersome and expensive, Airtorch® allows for inexpensive processes. | The Airtorch® can be used for curing, surface burning and sealing operations. The possibilities are endless as Air, Nitrogen, Helium and Argon can be used. |

| Large Die Heating | Direct Ceramic Drying |

| The Airtorch® allows large die heat-up; reclaim dies and aluminum.

| Free and bonded water can be easily removed. The Airtorch® can achieve very high temperatures without contamination, therefore direct drying is a natural application. MHI also manufactures several Airtorch® Continuous ovens. |

| Binder Burn Off | Heating for Tensile Testing |

Easy, uniform, safe, and collectable binder burn off. For ceramics, nitrides, powder metals, etc. Substantially improve quality and productivity. | When high temperatures are needed in spaces where resistance heating elements cannot be used, the Airtorch® provides the solution.

|

| Packaging or Sealing | Die Heating |

Designed for long life and high temperatures, the non-contaminating Airtorch® is an ideal solution for inline packaging or sealing processes. | Use the Airtorch® as a preheating device for dies in the metal forging and rolling industries. |

| Soldering, Melting and Dental | |

| Use the Airtorch® for softening, soldering, and melting of precious metals and glass. This feature is very applicable to the dental, jewelry, and glass industries. Use for rapid glazing, burnout and quick melts. | |

| Nozzle Heating | Gas Preheating |

The glass industry uses the high temperature Airtorch® to enable uniform flow and reflow of molten glass. The air temperature can be as high as 1200°C with a very low flow rate. | Airtorch® can be used to rapidly heat various atmospheres: Air, Nitrogen, Argon, Helium, etc. Call MHI for more information.

|

| Microprocessor Heating | Light Fiber Processing |

| Unique heating from 500°C to 1000°C. The Airtorch® produces laser-like heat to small areas down to 5mm in diameter with stable and accurate control.

| Uniformly free carbon from woven fibers with true convection. The Airtorch® creates hot turbulent air that passes through the substrate for uniform and accurate heating. As carbon is released, the natural flow of clean hot air flushes the airborne carbon away from the part and up the chimney. |

| Effective Heat Treating | Preheating for Welding |

Uniform rapid heating. The Airtorch® offers uniform high temperature and heat transfer to rapidly heat parts. Very effective for metals when increasing hardness. | With high accuracy and temperatures, the Airtorch® reduces the guess work out of preheating for welding applications. Offers accurate temperature read-out.

|

| Spot Decarborinzing (reducing hardness) | Ultimate Utility |

Over carbonizing causes hardness above most machining capabilities. The Airtorch® offers locatable, accurate rapid heat-up and cool down to efficiency diffuse carbon allowing tempering of the metal. | Develop your own application. The Airtorch® is capable of many applications where accuracy, uniformity, power and high temperatures are required. Also benefit from whisper-like operations, energy efficiency, and ease of use. |

| A comparison of the benefits of heating by convection and radiation at temperatures below 1000°C (1830°F) is presented in this article. The convective heating data is for a nonpolluting furnace that uses an electrically powered, ultra hot-air/ gas generator. The Airtorch source quickly and efficiently produces hot air or inert gas heated to temperatures as high as 1000°C (1830°F). The complete article is available in the October issue of ADVANCE MATERIALS & PROCESSES magazine (pages 213 to 215,10/1999). Read complete article and other similar articles Read Article on enhanced heat transfer coefficient with even small stable ionization |