High-Temperature Heating Elements

Industrial heating processes can be broadly categorized as low-temperature (to about 250 °C), medium-temperature (between 250°C or 750°C ), and high-temperature (beyond 750°C ). Low-temperature processes include cooking, drying, curing, molding, finishing, joining, and shaping plastics. Medium temperature processes include melting plastics and some non-metals for casting or reshaping, as well as annealing, stress-relieving, and heat-treating metals. High-temperature processes include industrial casting, heat treating, plasma, chemical reactions, material manufacture, and many more. MHI is an excellent source for your heating needs. MHI heating elements offer climate-sensitive materials and other patented compositions that enhance energy efficiency and sustainability. For more information, a free process heater comparison chart, or a quote, please use the form below or call us at 513-772-0404. Our trained sales staff can help you calculate flow rates, power, and inlet/outlet configurations specific to your application. Please use the form below to request information about MHI Products or general inquiries. Let MHI impress you with energy efficiency, sustainability, and climate change initiatives. MHI products are powered by modern materials and designs. Telephone: 513-772-0404 Alt Telephone Number: 513-286-1222 Alternate Mobile Number for WhatsApp 513-237-7755 Fax: 513-672-3333. Please note that providing a phone number gives us the permission to call/text you if required. By using the webform, if we are unable to email you or require additional information, please note that we may call or text you. We are happy to discuss energy benefit calculations.

Replacement Heaters MHI Furnaces and Other Brand Furnaces

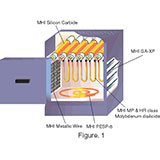

Information on Molydenum disilicide heating elements

Replacement Heaters for MHI Furnaces and for Other Brand Furnaces

Information on Molydenum disilicide heating elements

Replacement Heaters for MHI Furnaces and for Other Brand Furnaces

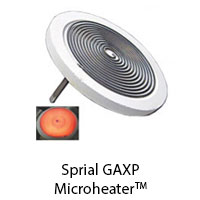

GAXP

200-1450°C

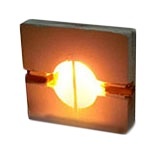

Robust Radiator™

800°C-1600°C

Connectors & Accessories

Are you tired of changing and paying for heating elements that don’t last even a year? Call MHI for new directions. Yes – we offer a one year warranty on several types of patented elements.

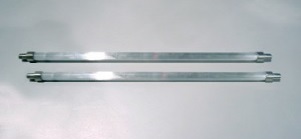

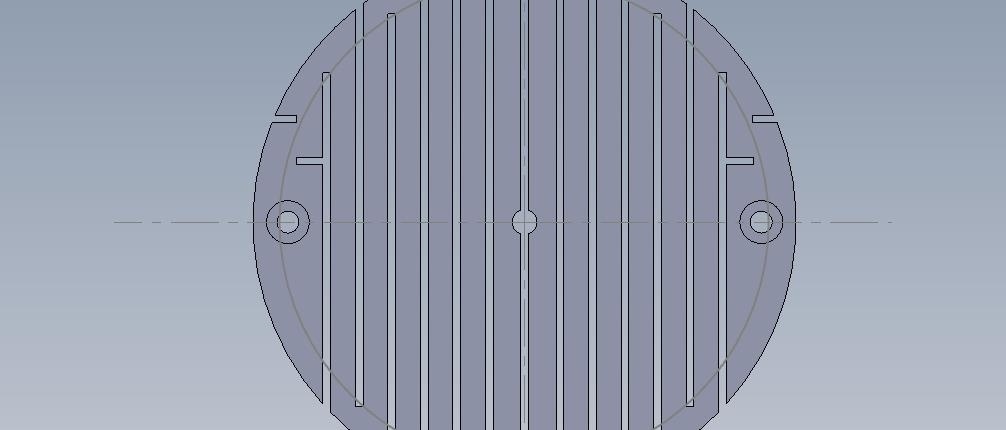

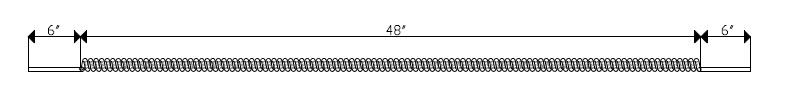

A Schematic of HotCoilRod(TM) heating element. Material GAXP(TM) (1450C)

Use for Large Furnace Applications. Both Low Power -coils. and High Power the HCR rods.

HCR(TM). Choice of single side terminal or both sides. Long Cartridge type.

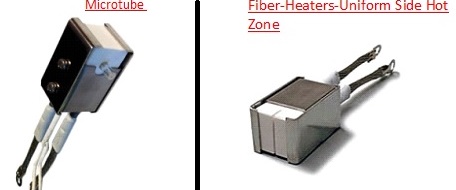

Ionic, Radiative, Convective and Steam Heating Tools

MHI Inc. is an integrated manufacturer of heating elements, heater elements and high temperature tools. We have been awarded numerous patents for our novel, high quality, and durable heating products. Our products speak for themselves.

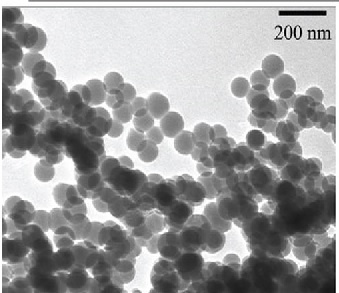

Suggested applications include: Furnaces (both MHI replacements and Others), AC/DC Electromagnetics, Acoustics and Vibrations, Batteries, Fuel Cells, and Electrolytic Processes, Bioscience and Bioengineering, Chemical Reaction Engineering, Computational Fluid Dynamics, Electromagnetic Heating, ceramics and composites, melting furnaces, Geophysics and Geomechanics, Tool Bits, Coatings, Hardfacing, Fuel Development, Shrink Label and Shrink Wrap, On Rigs Syeam, Heat Transfer and Phase Change, MEMS and Nanotechnology, Microfluidics, Multiphysics, Optics, Photonics and Semiconductors, Optimization and Inverse Methods, Simulations, Particle Tracing, Piezoelectric Devices, Plasma Physics, RF and Microwave Engineering, Simulation Methods and Teaching, Research projects, Structural Mechanics and Thermal Stresses, Subsurface and Porous Media Flow, Transport Phenomena, ovens, heaters, replacement heaters. high flux heaters. Try out GAXP spirals in ESEM and SEM use. Try S12-200 as a source.