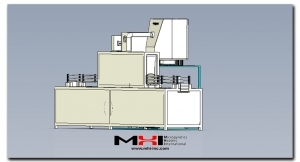

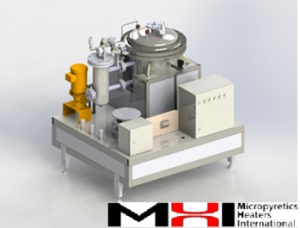

OAB® Energy Efficient Electric Steam Generation Models.

Set the flow and temperature, then hit start. It’s simple.

From 1 kg/h to large tons of steam/h (MW systems).

- Versatile Electric Steam Generators for the Highest Energy Efficiency. This results in a faster rate of payback and a more productive, stable process.

- Energy Optimized: Set the temperature, flow rate, and power on the start-up screen.

- Precision – Set it by the numbers on the touchscreen HMI. Set it remotely. Set the pulsing frequency as required. Highly automated.

- Safety Optimized: No need to operate at high pressure to get high-quality superheated steam. You can choose your pressure.

MightySteam®

- Operates on demand with no stuck valves—electronic flow control is provided for an instant on and off function.

Introduction to Steam and Humidity, Steam Generators and their Applications.

Technical Specifications of Steam Generators

| Model | Image | Temp. Range | Pressure Rating | Efficiency (nominal best to use only as an approximate guideline) | Application |

|---|---|---|---|---|---|

| MightySteam OAB (variable) Premium model with variable flow rate and temperature features. Heavy Industrial. |  OAB Electric Steam Generators. Decarbonized. | Up to 1200°C Models from 5 kg.hr to tons/h, kW to MW Modern electronic flow rate valves and HMI settings. | Atmospheric- 40 bar | High 95%+ | Sterilization, chemical processing, food industry, CPG packaging. Pharmaceutical, textiles, HVAC, Testbeds. More Information |

| HGA-S or OAB fixed Models for innovation prototyping. |  HGA-S-01  OAB-12-750 | 300-1200°C 1 kg/h.with steam side valveor OAB, fixed flow 4 or 12 kg/h (fixed) with steam side valve. 750°C temperature | Atmospheric | 95%+ | Sterilization, chemical processing, food industry, CPG packaging. Pharmaceutical, textiles, HVAC, Testbeds. More Information |

| HGA-M |  | 300-800°C 1 kg/hr. or 4 kg/h. | Atmospheric | 95%+ | Medical sterilization, laboratory applications, and mobile applications More Information |

The variable flow range will change based on the requested maximum temperature.

OAB-Var with a maximum of 6, 8, 10, or 12 kg/h.

OAB-Var with a maximum of 12-25 kg/h.

OAB-50-Var models (20-55 kg/h Steam)

OAB-100-Var models (70-130 kg/h Steam)

OAB-180-Var models (130-220 kg/h Steam)

OAB-360-Var models (240-440 kg/h Steam)

OAB-750-Var models (360-660 kg/h Steam)

OAB-1200-Var models (1.2 tons/h Steam)

OAB-2700-Var models (3 tons/h Steam)

OAB-4 tons/h

OAB-10 tons/h

OAB custom models… please contact.

Set the temperature and flow rate on the touchscreen display. Directly interface to humidity and other sensor signals. Monitor power and energy efficiency. Set pulse rate for instant high-temperature electronic valving

Users save energy and enjoy improved efficiencies (greater than 98%) with no CO2 emissions. On-off, high temperature, and adjustable steam parameters permit process optimization with the touchscreen or remote adjustment (via the Ethernet) by adjusting the temperature and steam flow rate settings. Steam production is almost instantaneous after a backfill. No requirements for additional blow-down machines make the OAB steam generators much lower in equipment, energy efficiency, and operational costs than comparable-size boilers. The external controls of temperature, humidity, and other parameters via the PLC make the systems customizable for specific user applications.

Request a quotation. We will need to know the steam flow rate range (kg/h), temperature output range, and the system back pressure.

Features:

- Electric-powered operation eliminates fossil fuel use and eliminates greenhouse gas emissions.

- Precise temperature and pressure control for enhanced process efficiency and accuracy.

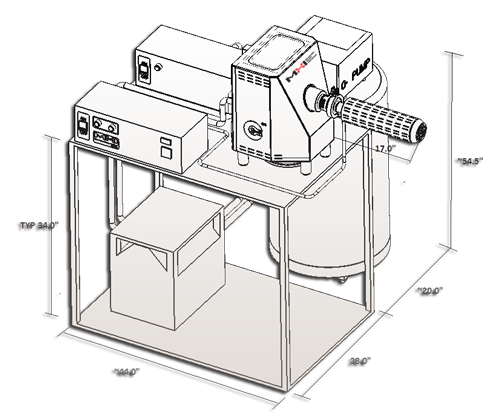

- Compact design and modular configurations for flexible installation and easy scalability.

- Advanced safety features and compliance with industry standards.

- Simple to use. Easy to ins all. It saves energy and improves process productivity. Meets the requirement for deep decarbonization.

Programmable steam temperature, high-quality, adjustable rate, continuous superheated steam production. Easy incorporation of process triggers via Ethernet — touch screen controls—rapid returns on decarbonized equipment.

- Save substantially on electric costs.

- Choose models up to tons /hr. Choose output temperature—Request Quote.

- OAB® units offer unique full-back pressure capability as required. On-off at ill. Steam temperature is achieved within minutes. No idling is necessary. Advanced PLC and HMI controls. Ethernet-enabled.

- Steam on-demand, high-quality 100% clean steam, and low condensation contribute significantly to the high steam-making efficie

ncy. For steam generators, instant Steam-on-demand is enabled with electricity on/off without storing Steam (energy) in a vessel.

ncy. For steam generators, instant Steam-on-demand is enabled with electricity on/off without storing Steam (energy) in a vessel. - Choose models up to 200°C, 300°C, 800°C, or 1000°C and higher. Set the temperature and flow on the touchscreen HMI. Please discuss.

- Electric steam generators, such as MightySteam® and OAB®, do not produce greenhouse gases like CO2, Methane, or NOx—only Steam.

- Innovative and Modern: There is no need to specify a high pressure when the requirement is for high-temperature Steam. Specify a pressure requirement only to overcome the back pressure in a process.

- Modern communication protocols for external/remote management (such as setting the temperature, setting the flow rate, or creating event triggers) are safety features for remote operations.

- Modern leveling features.

- Avoid costly ancillary operations and equipment associated with traditional boilers.

Choose from Single Phase 4 -12 Kg/hr to three-phase 40-3000Kg/hr variable steam rate.

Save on electric costs by using on-demand power for the required low. Steam generation is almost instantaneous.

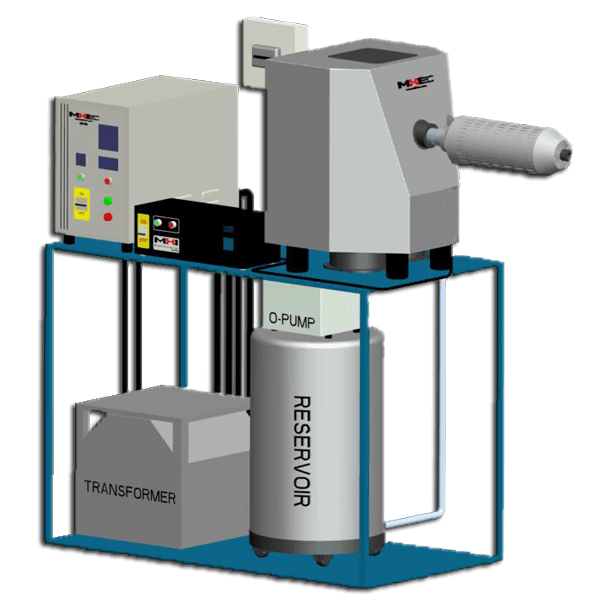

The steam generator draws water from the tank and converts it to Steam. The Steam discharges quickly through a standard pipe. The flow and temperature can be varied with the control panel. This innovative technology has been designed to provide high-quality Steam in a highly efficient and reliable manner.

- OAB® units offer independent control of steam temperature and flow rate. They now offer variable flow models for the 1 – 3000 kg/hr steam range. Control features are provided so that the user has broad flexibility to optimize a process and energy use.

- For steady-flow units with a standard selection of flow rate and temperature variability, please specify the OAB® model from the table below.

- Instant Steam. Compact units for tons/hr.

- For 340 kg/hr, 750 kg/hr, and 10,000 kg/hr, please contact MHI.

- Use for chemical processes, steam drying, antibacterial, plastics cleaning, dry-cleaning, and much more. Please specify steam quantity Kg/hr, required steam- temperature, and backpressure rating. The backpressure rating will determine the shell rating requirements.

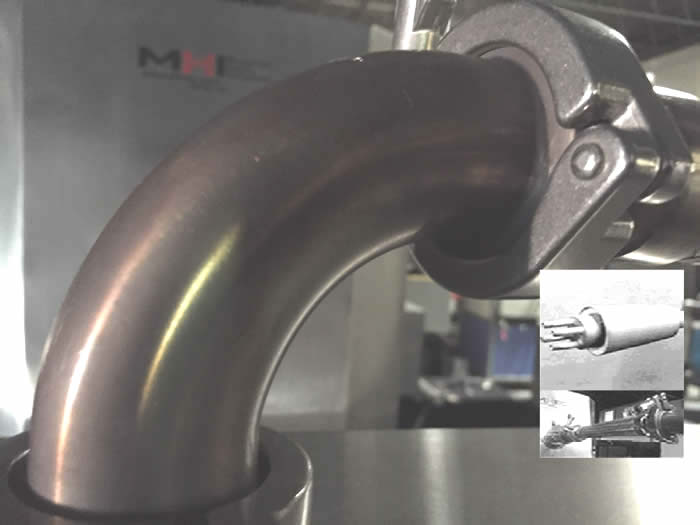

- Easy Connectors and Steam Tube Extenders.

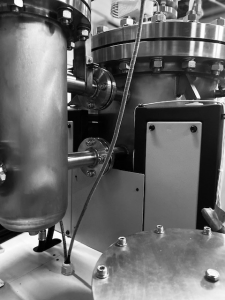

- The adjacent pictures show an easy-to-attach K-type clamp connector, the OAB-12 300, and the Extender Vittori Tube.

- The OAB-4 has steam side valve options for regulating the Steam.

- The OAB models offer steam flow regulation with electronic logic controls.

Energy Savings and Improved Uniformity with Steam – Deep Decarbonization.

Save Money, Save Energy, and Improve Productivity. Become aware of faults and take corrective action before they become a problem.

- Instant on-off. No idling type wastage.

- Control the steam directly with an RH meter or other input.

- Compare the energy efficiency of a steam generator to a conventional boiler. You may be surprised to see a 50-100% improvement in the energy used.

- Rapid steam production, from 25C water to instant steam at 180°C, 300°C, 800°C, or higher.

Elegant, Easy to Use Steam Generators and Panels

- Enjoy the related water savings.

- Compare footprint and ease of operation.

- Noncondensing steam above the inversion temperature. Much lower condensate waste.

- Compare Steam Generation Methods.

| Available Steam Models. Please contact MHI for more details. | |

| R&D Models

Elegant Easy Steam Generators and Panels Choose temperatures between Saturated and 1000C. —————————————————– Single Phase. Limited flow variation is available.

—————————————————– Single Phase Variable Flow and Back Pressure Enabled.

| Industrial Models

A 25-10,000 Kg/hr Instant Steam Generator for 24/7 Industrial Use Choose temperatures between Saturated and 1000C. Three Phase. Infinite flow variation is available across the range mentioned.

|

| OAB- 12 Models Fixed Flow 12kg/hr. | Typical Model Pictures | Steam Produced (nominal) | Total Electric Power Exit Temperature(nominal values) |

|---|---|---|---|

| OAB-12-300 (Maximum Temperature 350-400°C) OAB-12-550 (Maximum Temperature 550-600°C) OAB-12-800 (Maximum Temperature 750°C) |  OAB-12-300

OAB-12-550 | 12 Kg/hr Steam | OAB-12-300 is about 400C OAB-12-550 is about 550C OAB-12-800 is about 750C Variable flow models are available. See table above. please note units can be one atmosphere rated or rated to higher pressures like 3 Bar- please specify |

Steam Rate Flow Adjustment: Discrete and Continuous Mode is Available

Optional cN-BPE for continuous adjustment of steam rate.

Optional: Addition of gas to steamers.

Steam velocity above 50m/s depends on the model.

|

Simple to use for instant steam production and desired flow rate, with HMI/PLC controls

Transforming Steam Technology For Significant Energy and Water Savings. The savings efficiencies reported range from on to off. There is no requirement to heat any tubes or nozzles to produce steam. Conventional boilers are never 100% dry, unlike conventional boilers’ where the heat loss causes steam to condense and become wet as it travels down the steam line. Decreased steam dryness hinders heat transfer; it is, therefore, important to monitor steam dryness to provide optimum heating efficiency for your system. The OAB® steam is very dry.

Steam Connectors

cN-BPE Connector for OAB-4

Instant Steam

Steam generators allow the setting of the required steam flow rate, backpressure, and temperatures.

GOAB-6 Variable flow (2-6 Kg/hr. Steam) OAB-4 Fixed flow 4 Kg/hr. Steam GOAB-12 Variable flow (12-24 Kg/hr. steam) OAB-12 Fixed flow 12 Kg/hr. Steam OAB-Var 25 Kg/hr 750C (15-25 Kg/hr.) – syngas production starter model (25 Bar). OAB-50-Var- Models (20-60 Kg/hr. Steam) OAB-100-Var-Models (70-120 Kg/hr. steam) OAB-180-Var Models (120-220 Kg/hr. Steam) OAB-360-Var Models (240-440 Kg/hr. Steam) OAB-750-Var-Models (360-660 Kg/hr. Steam) OAB-1200-Var-Models (1.2 Tons/hr. Steam) OAB-2700-Var-Models (3 Tons/hr. Steam) |

|

Pure Steam. Clean Steam. The versatile OAB® Steam Generators/Boilers from MHI generate instant superheated Steam free of water droplets. The steam generators offer noncondensing dry Steam above the inversion temperature for rapid drying operations. The Steam is ideal for utility steam, pharmaceutical, cosmetics, chemical and fuel processes, antimicrobial, and other applications requiring high-quality Steam. Steam is also suitable for comfort humidifiers and similar applications because of its easy controllability.

Compare the price of electric steam generators to fossil-fired boilers for:

- Energy efficiency (electric steam generators are often 96% or more energy efficient)

- Cost of climate-altering fuel emissions at the use site ($0) for electric steam generators,

- Energy loss from the hot flue discharge of fuel emissions ($0 for steam generators anywhere from $51-$500 kg per ton of CO2 emitted).

- Cost of ancillary equipment such as blow-down equipment (not required for OAB steam generators).

- Check availability of touch screen settable variable temperature and flow (yes, for OAB steam generators).

- The size of OAB steam generators is often much smaller than that of pressure boilers.

- High productivity from proper power usage and power management systems

- Automated functions such as phase and water quality sampling.

- Water savings.

OAB Models.

| GOAB-6 Variable flow (2-6 Kg/hr. Steam) Electric Panel Rating Options UL, cUL, and CE. | Click here for variable steam models.

|

| GOAB-12 Variable flow (12-24 Kg/hr. steam) OAB-12 Fixed flow 12 Kg/hr. models Electric Panel Rating Options UL, cUL, and CE. Watch the video for the OAB-12 fixed-flow model. | Models for Steam up to 800°C+. From 12KW electric power. Click here for variable steam flow very high-pressure models.  OAB Control Panels |

| OAB-50 Electric Panel Rating Options UL, cUL, and CE. | 50 Kg/hr. Models for Steam up to 800°C. Adjustable up to 50 KW electric power. Variable Flow. Backpressure up to 50 Barg ratings available. 240V 3 Phase |

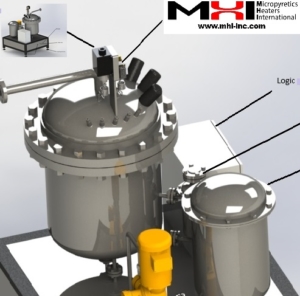

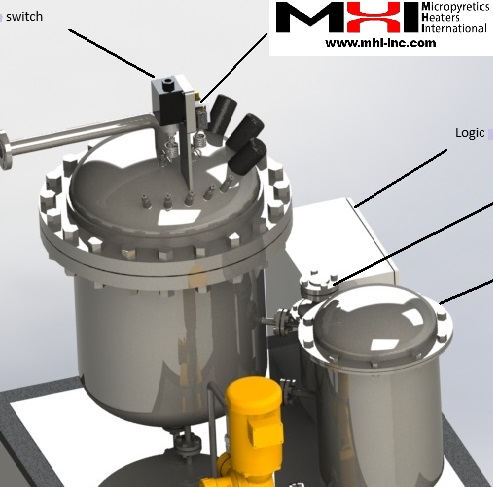

| OAB-100

A third-party rating for the pressure vessel is offered (Section V111. Div. 1). Electric Panel Rating Options UL, cUL, and CE. | Variable flow from 70 Kg/hr to about 120 Kg/hr. It can be adjusted up to 100 KW of electric power. Basic Model (up to 300°C) High-temperature models for Steam up to 800°C and higher. Backpressure up to 50 Bar rating available Offered with a logic panel  HMI operations enable easy use of the heavy-duty steam generator |

| OAB-180 A third-party rating for the pressure vessel is offered (Section V111. Div. 1). | The flow variation is 135 Kg/hr. to about 1200 Kg/hr., and it is variable. The electric power is adjustable up to 180 KW. Basic Model (up to 300°C) High-temperature models for Steam up to 800°C and higher. Backpressure up to 50 Bar rating available Offered with a logic panel |

| OAB-360 A third-party rating for the pressure vessel is offered (Section V111. Div. 1). | Flow variation 200 Kg/hr to about 360 Kg/hr Basic Model (up to 300°C) High-temperature models for Steam up to 800°C and higher. Backpressure up to 50 Bar rating available Offered with a logic panel |

| OAB-750 A third-party rating for the pressure vessel is offered (Section V111. Div. 1). Electric Panel Rating Options UL, cUL, and CE. | Flow variation 300 Kg/hr to about 750 Kg/hr Basic Model (up to 300°C) High-Temperature Models. Models for Steam up to 800°C and higher. Please specify if the variable flow is required. Backpressure up to 50 Bar rating available Offered with a logic panel |

| OAB-1200 A third-party rating for the pressure vessel is offered (Section V111. Div. 1). Electric Panel Rating Options UL, cUL, and CE. | Flow variation 750 Kg/hr to about 1200 Kg/hr Basic Model (up to 300°C) High-Temperature Models. Models for Steam up to 800°C and higher. Backpressure up to 50 Bar rating available Offered with a logic panel |

Replace all boilers with on-off steam generators. Choose flexibility and a high degree of control.

Comparing OAB® instant (within minutes) steam-generators to others:

- High-quality, high-temperature steam is made within a minute. When not required, the unit can be switched off. There is no idling required. Suitable steam generators provide instant on/off capabilities, which saves energy. The system cools down quickly, with no chambers or pipes to cool off.

- A temperature above the inversion temperature without the need for high pressure leads to energy efficiency and a reduced amount of steam wastage.

- Zero exit condensation.

- Click for laboratory scale 1300C models.

- The controls include phase-angle SCRs, soft start, and other modern features that enhance the element’s life. The controls include PLC and HMI.

- The energy efficiency from cold water to steam estimate is ~95%. Many companies may claim this, but on a closer examination of the numbers, one may find that the base for the energy estimation could be pre-boiled water, one that ignores the long start-up cycle time. The correct energy efficiency compares socket power to steam power with the base energy of room-temperature water converted to steam. Low condensation leads to improved efficiency.

- The unit uses 50/60Hz. OAB® steam Generators do not use high frequencies like the induction frequencies that can disrupt modern plants.

- ASME Section V111 Div 1 and other ratings are offered.

- OABs independently control steam temperature, steam rate, and pressure. This is not old boiler technology. It is the modern instant steam technology. Do you have to use special equipment for blow down?

- Some competitors use generators for pipe heating, which then heats the fluid. Such technologies translate to heating thick, high-pressure pipes with external heat. Such systems are energy inefficient and could also be the source of pie-ruptures at high temperatures.

- The OAB offers a low number of external connectors compared to other steam generation methods. Just one connector to the user’s pipe is required for the OAB.

- The backpressure rating will determine the shell rating requirements. This feature allows for money savings if backpressure is not required. Steam generators do not need to generate high pressure for high-temperature steam.

- The OAB has a compact footprint and is, therefore, easily locatable at the point of use.

- Easy Connectors. The units provided are completely operational – the user does not need to purchase additional parts to operate the units.

- Steam quality is very high—no water droplets.

- The most important feature of a steam generator is that it is a continuous process and can run for short or long durations.

- The system is designed with sustainability goals in mind. Because steam production is instant – within a minute, one does not have to plan a shutdown or start-up outside working hours. The water input is continuous but only when required for operation. Unlike Boilers and their modern cousins – no extraordinary chambers are used for boiling. This gives plant-wide operational flexibility and offers high energy efficiency.

What is the yearly Operational Benefit of an MHI 16kW steam generator over a 300kW traditional boiler?

- Worker Safety – some guidelines.

OAB®-4 Models Models for 300°C, 550°C, 800°C, 1300°C Steam 4Kg/hr Click to Contact. Dry Steam.

OAB® -12 Models Models for 300°C, 550°C, 800°C Steam 12Kg/hr Click to Contact. Dry Steam.

GHGA Models where pressure and temperature are required for 6 or 12 Kg/hr steam.

MHI’s One Atmosphere Boiler superheated steam boiler features patented InstaSteam™ technology, allowing for rapid startup times, unparalleled efficiencies, and up to 1300°C temperatures. BoilerFree™ technology allows most OAB® units to be installed without traditional boiler certifications. The OAB® is ideal for use as an industrial steam generator, for de-wrinkling operations, superheated steam drying, and dozens of other specific applications requiring a high-efficiency boiler that does not require boiler certifications—so many great uses in packaging, textiles, drying, and more.

Highly Scalable.

Compare Efficiency. Three types of efficiencies are essential to consider. (1) the efficiency of the steam generation device where the OAB® and MightySteam® excel; (2) the efficiency of the downstream process that the steam is used for; and (3) the overall water usage efficiency and propensity to recycle the water. The one-atmosphere steam-gas generator/boiler performs well in all three categories.

Controls: Modern controls with logic PLSC and touch screen HMIs are used for the industrial models.

Plug N Play – The OAB® devices are very user-friendly for installation.

For more information – click on,

Micropyretics Heaters International One Atmosphere Boiler (OAB) is 100% dry.

Plug-n-Play, Easy Piping and Connectors

How does one increase the production rate for drying with Steam – other steam applications?

The Short Answer is to increase the process gas or steam temperature and use a high-efficiency steam generator for high-quality steam.

Long Answer: Please click through to the Steam Calculator page.

Better conversion allows the OAB® units to use fewer resources to produce more steam. A standard OAB® steam output at 300°C or more is obtained – almost the theoretical efficiency of power conversion. The OAB’s rapid start-up (generally within a minute of the fill from a cold start) – considerably lowers energy usage overall. No moisture is noted even at start-up.

| Water Flow Indicators on OAB | Connectors. Easy for OAB. |

| |

Several indicators including | When individual streams of steam Vittori™ Tubes for Steam Discharge |

Getting to temperature quickly and faster results in lower operational wear and related costs i.e. an overall higher productivity with

corresponding higher kinetics. The output velocity of the 550°C OAB® steam is very high – almost 40m/s or more. This feature is used for the uniform heating of kettles/heat exchangers and for reaching large piping distances without significant loss of temperature. For industrial vats and kettles, the heating rate makes a considerable difference to the overall process economics. A general rule of thumb of productivity from traditional pressure boilers is – (0.35 Gallons of a heated product like water)/kWhr. For the OAB-4® it is closer to – (1 Gallon/kWhr) i.e. almost three times (numbers may be lower or higher as they are situationally dependent and one needs to evaluate on a case by case basis). Industries served for during. Please also see Single Phase OAB and Airtorch®.

The OAB® offers a scalable design and because of the small foot-print qualifies for the MHI Never-Down policy. The scalable design allows

the user to choose what fraction of the boiler needs to be turned on on a given day or hour and changed at will. MHI electronics provide

full data logging, on-screen data acquisition display, and a repertoire of 100 programs – all in the small sophisticated control panel.

How do Temperature and Pressure Impact a Steam Reaction?

OAB® and GHGA Compared to Traditional Boilers.

Steam Calculator, Productivity Enhancement and FAQ’s |Physical Properties of Moist Air/Gas | What are Steam and Humidity?

Synopsis and video, Steam Calculator, Productivity Enhancement and FAQ’s, Physical Properties of Moist Air/Gas

What are Steam and Humidity? What is mist and fog. High Efficiency Steam Recirculating Ovens

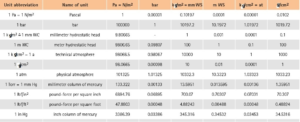

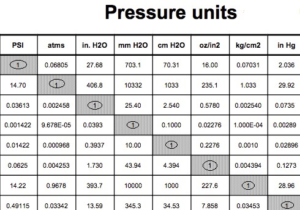

Convert kW to BTU/hr

1 kW = 3412.142 BTU/hr

One Boiler HP (Boiler Horse Power)= 33,500 BTU/hr = 9.803 kilowatts

More Calculators for Engineering Units. Please click here.

Steam Calculator – Superheated Steam. Click here.

Want to find out how MHI can help you meet your steam needs?

Please fill out a quick questionnaire by clicking on the product of interest.

We will help find a good solution to meet your needs.

Click here to add your own text