Steam Generator Models

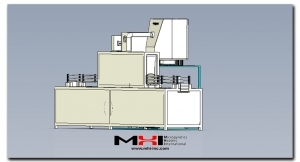

- MHI Inc. offers a versatile and patented portfolio of high-temperature steam generators. The available models include pure 100% quality steam generators to steam-gas mixture generators that start up within seconds. New models for steam plasma and steam chambers.

- All models are powered by premium MHI electronics that have been tested for over two decades in universities, industries, and research

Large Decarbonized Steam Generators

laboratories. For several models set temperature, flow and frequency on the touch-screen HMI and say go.

- The use of MHI steam can enable significant energy efficiencies for downstream applications in chemical processing, steam heat, bio waste, the food industry, and many others.

- Please click on a category picture below to explore the steam models, prices, and delivery options when listed in the comprehensive MHI web store.

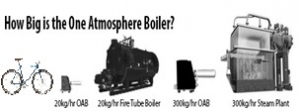

- Why MHI steam generators? (1) Efficient electric models (2) Easy installation and maintenance (3) Compact and versatile power ratings (4) Variable flow, variable temperature, variable pressure in one unit; tuned for a host of applications.

Fundamentals of Steam

GHGA™ and MHGA™

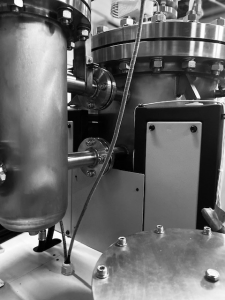

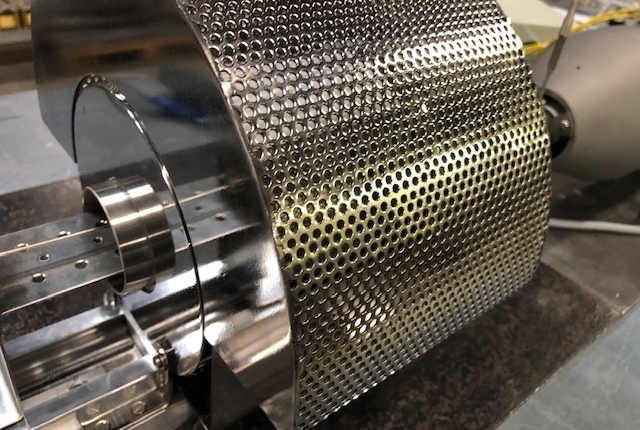

Independent High Temperature, High Flow and High Pressure Steam

Steam Plasma

Please contact MHI with Details of the Application

Steam for Packaging and Textiles. Click.

Want to find out how MHI can help you meet your steam needs?

Please fill out a quick questionnaire by clicking on the product of interest.

We will help find a good solution to meet your needs.

Resource Pages

Productivity Enhancement and FAQs

Physical Properties of Moist Air/Gas

High-Efficiency Steam Recirculating Ovens

————————————————————————————————————————————————————————

Steam Applications

———————————————————————————————————————————————————————————

What is MHI working on to help with global warming apart from its standard-proven approaches? Did you know MHI shares data openly when it is of public interest- of course, only whenever it is free to share? Please support us by purchasing MHI products.

Interesting methods are below. Hint: Look carefully at the reactions.

Futuristic reactions. These are discussed only with MHI’s high-value existing partners. License possibilities to technology and trademarks.

2CH2O(g) + 2H2O(g) = CH3OH(l) + O2(g) above ~1320C Formaldehyde to Methanol

CO2(g) + 3H2(g) = CH3OH(l) + H2O(g) above ~1320C Methanol by heating Syngas or just heated CO2(g)

Greenhouse gases like CO2 can be converted to various types of alcohol.

Waste to Fuel reactions can also be considered.

Interesting reactions possible above 1435C:

2C + 4H2O(g) = 2CH3OH(l) + O2(g) Carbon to Methanol (solid to liquid fuel type reaction with hot steam – (use Quasi-R® catalysts)

and Photosynthesis

6CO2(g) + 6H2O(g) = C6H12O6(Sugar -GAa) + 6O2(g) Yes negative free energy at MHI high temperatures. Call MHI.