Airtorch® Air and Gas Heater Models by Category

Deep decarbonization and clean energy use are competitive advantages of MHI Airtorch configurations.

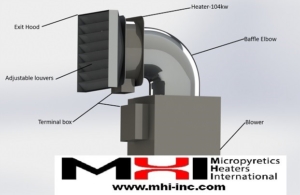

Bay door heaters

Several electric process heater models are available in each class (Kilowatt to Megawatt models)

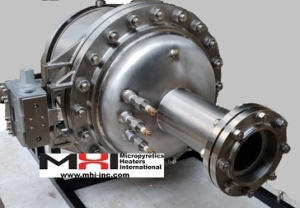

- Large Flow GTA (In-line, test-bed, high-pressure) Models

- Large Flow (Energy-efficient comfort flows) Models.

- DPF, VTA-MPDNA, and GPD-MPDNA (Very high temperature) Models

- LTA–VTA-MTA-MVTA Models (for process air)

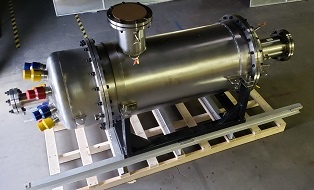

- MTA925 and GTA925 (Sealed Gas) Models

- New: Inline-Airtorch™ models for process heat are now offered with input up to 20°C-800°C into the Airtorch™ and output up to 1200°C (~2150°F).

Please contact MHI for Airtorch™ and Airtorch™-recuperation uses. Smart Recuperaters,

Typical Applications include Simulation, Chemical Reactions, Heating Reactions, Drying, and many more.

Simple 5-step selection guide and flow as a function of temperature for various models.

Suggested Uses: Process gas heater, gas heater, decarbonizing heater, gas preheater, air preheater, supplemental heater, and many other process-heating applications. See Applications

The required kW depends on the exit gas’s temperature from the Airtorches® and the flow volume needed. Please use this formula to calculate the approximate temperature vs. flow rate for a fixed power or an Airtorch® model number. MHI also provides flow rate vs. temperature. Request graphs here.

Introduction to Airtorch | Airtorch Applications | Calculating Power vs Flow Rate | Easy Design Criterion | Properties of Gases and Moist Air with Temperature

Large Flow. For 400-1200°C. Experience low-pressure drop savings. Duct Heaters. Process gas heaters with a blower or inline capability. High KW to High MW. – High Flow. Contact MHI.

Typical Applications for Airtorch®:

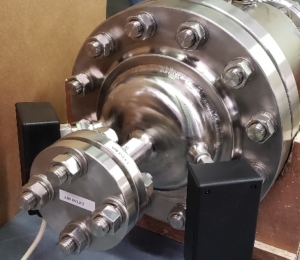

- Several applications are in high-pressure test stands for automotive and jet engines— key Features: Long-lasting, high temperature, high energy conversion, high pressure, and compactness.

- Electric hot air generators are often used to heat commercial and industrial environments. Several applications are in energy-efficient comfort heating. Key Features: Compact, long life, and rapid heating.

- Several applications in chemical processes and drying. Key Features: Energy efficient, extremely compact, controlled high temperature, and rapid heating. Airtorch® nano-structuring is used for gas combinations like hydrogen, methane, or syn-gas where combined catalysis action is enabled.

- Use in Ammonia, Cement, Steel, and General Heating Industries

Each type of application has its unique control system designed for that market.

MHI Airtorch® systems offer patented low-pressure drop technology called the Direct Flow method—industry-leading quality, price, and delivery. Several models are displayed below. Units for 750°C,925°C, 1000°C,1100°C and 1200°C. The typical Airtorch® use is illustrated in the Airtorch® Infographic.

Why are the MHI Airtorch models efficient? Prices are scaled with power, temperature, and pressure. Please discuss your best value with MHI. The following classes are available: Flow GTA – For high-pressure vessel Airtorch use—custom engineering. Please contact us directly for assistance.

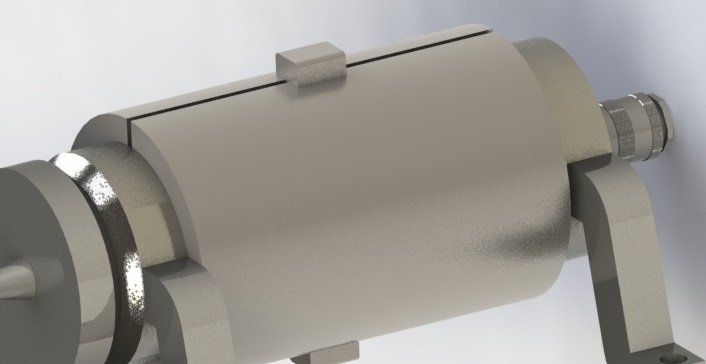

Airtorch™ and LTA’s may be purchased with several exit configurations generally shown on the specific web or catalog page. In addition, further customization is also possible.

LTA models are process air heaters designed for compressed air/gas input. LTA models offer temperatures up to 850°C. LTA models work with compressed air.

VTA models are process air heaters designed for use with fan/blower (max. back-pressure of 50 w.c./inches)

VTA models 600°C – 1200°C models.

VTA750-4GS, (4 kw)

Please click here for High-Power, 3-Phase, High-Temperature Models GTA Airtorch®.

From 2 to 45 MW and higher. Efficient Compact and Versatile. Contact MHI.