Single Phase Airtorch® Models

Flameless hot-air process heater models under 12 kW. Typically, single-phase operations. Click here for Large Flow 3 Phase Heavy Duty Airtorch® Models. This page is for electric process heaters with a capacity of less than 12 kW. Please click here to visit the Airtorch home page for high-KW and high-MW heaters.

This page provides information on small power (1-15 kW): ZTA, MTA, LTA (models without fans), and VTA (models with integrated fans).

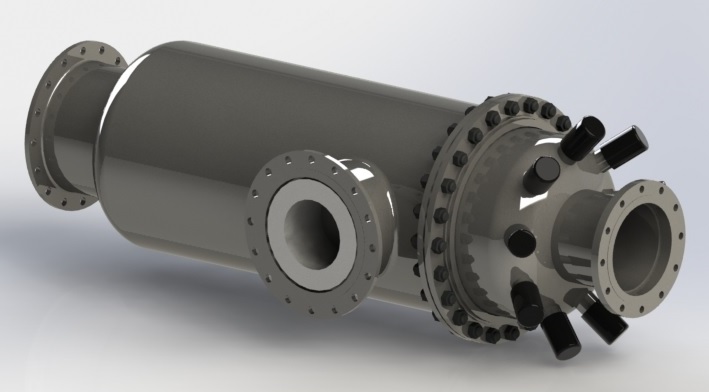

VTA Airtorch®

VTA models are process-air heaters are designed for use with a fan/blower except for certain models.

VTA models are typically used between 400°C – 900°C exit gas temperatures.

Fan controls (FANCS) are provided as an option for several VTA models.

Electrical comfort heating solutions designed to reduce CO2 emissions

(30KW, 60KW, 100KW, 200KW, 1000 KW, 5MW)

Electric weed killer industrial/commercial use. See Video.

![]()

LTA

Airtorch®

Models

1 KW to 10 KW Single Phase

110V-208V-230V-240V plug-in.

Use for Air Heating with compressed gas input

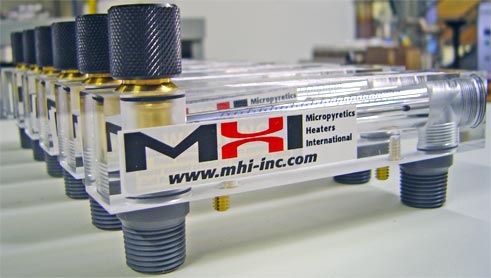

MTA/GTA

Airtorch®

Sealed Models

The MTA925 delivers heated air/gas up to 950°C. Unlike the LTA, the MTA is a fully sealed unit.

Click on the picture above for smaller 2 KW models, 4 KW Models, and 12 KW Models.

MTA (950C). Sealed one-atmosphere use. Click on the picture below for high-pressure or high-flow rate models.

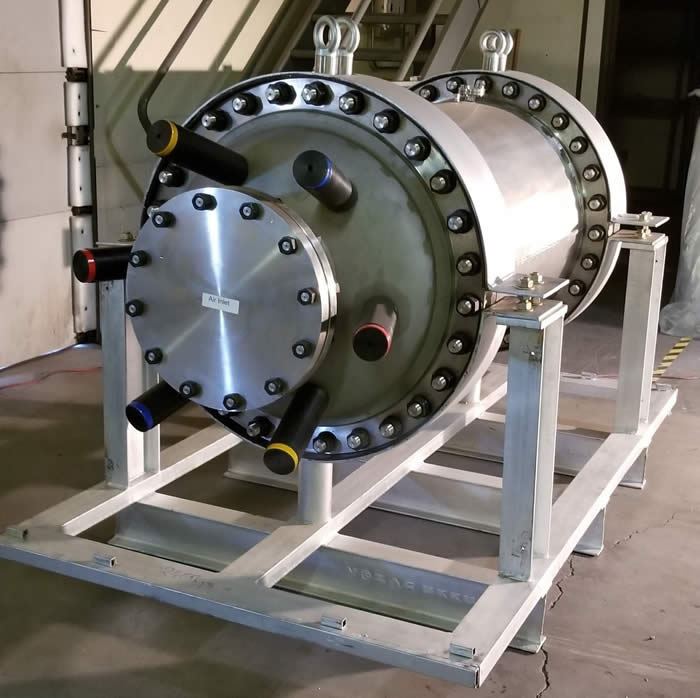

MVTA RR-Airtorch®

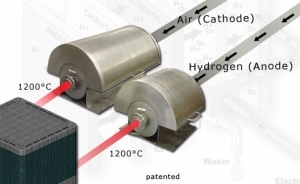

MVTA models are process-gas heaters designed for reactive and combustible gas input. They offer temperatures up to 1000°C and work with compressed air. Exit and inlet diameters and threading are described below, along with each model number.

For extremely low flows, ~0.5 SCFM up to 1200°C. They are typically used for Fuel Cell Laboratory Demonstrations.

Click on this model for high temperature >1300C

Click on this model for 1100C and lower.

For high-flow rate models, click on the picture below.

High Performance Small KW Models for R&D Work.

- MTA up to 900C or lower. Single Phase 900C (12 KW). Fully Sealed.

- ZTA-SL up to 1150C. Single phase 1150C (3 KW). Fully Sealed.

ZTA models are process gas heaters designed for reactive and combustible gas input. They offer temperatures up to 1150- 1200°C with gas. Contact MHI for information on exit and inlet diameters and threading.

- VTA models are used with fans and blowers; see the video of an electric hot-air weed killer.

- LTA Models are for use with compressed air input fittings.

- MTA Models are sealed for inline use.

If the flow rate is 2-40 SCFM and the temperature required is below 925°C, please choose from the MTA, VTA, or LTA models or the MVTA925 flanged units. If the flow requirement is higher than 40scfm or a pressure requirement, or if a very low-pressure drop is required, please choose from MVTA or GVTA models. Please contact MHI for assistance with model selection.

Airtorch® units have several safety features like the over-temperature and low flow cut-off features (model dependent). Please click on the individual model for more information, including price and delivery. If the required exit temperatures are above 925°C, please send a request to MHI with details of the request, and we will offer the most suitable model for you. Please always feel free to contact us.

Why use Electrical Controls? For any Airtorch® with fixed power, there is a flow rate that will give you the maximum temperature or a higher flow rate that will give you a lower temperature. For example, the LTA-10 will provide a 900°C exit temperature with ~20 SCFM. The unit plugs into any voltage between 208 and 240 V single phase.

The XPAN or BPAN-O-PLUS (Electrical Control Panel) can do the following. (1) Set the maximum temperature (or allow programmed temperature) not to be exceeded at any flow rate that is in the flow-temperature envelope, (2) Use the OTC function to not exceed a temperature at any location that you choose, and (3) provide a soft start with the phase-angle-controlled SCR so that the unit operates smoothly, thereby enhancing life.

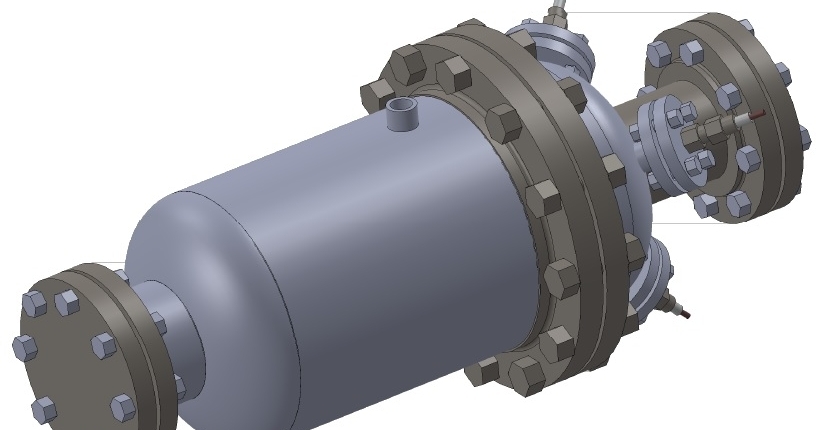

Large Power or Flow MVTA and MVTA-DPF models

Please click here Higher Power 3 Phase, High-Temperature Models (MVTA and GTA Airtorch Models)

Comfort Airtorch 100 KW

Flow Temperature Curves / Airtorch Application Information Page

- Use for heat tracing. Canopy-type operations,

- Use for low-cost preheating

- Airtorch® Operation: The flow rate and temperature are related. The air/gas heater should not be used beyond its rated temperature or power. The thermocouple is integral to the heater. The principle of an air/gas heater is for flowing gas to heat within the residence time of the heater/configuration.

- Flow Rate is Important: If using a blower or fan, the airflow will be controlled by the fan’s or blower’s characteristics. Fans are employed when the drop in pressure of the system is no greater than approximately 50 in. w.c. (50 in. w.c./inches of H20 is approximately 1.8psi.) This condition remains true even when the fans output large CFM. Blowers are considered in circumstances where more significant pressure drops are present.

- When the inlet flow is pressure-driven for LTA and MTA, the flow rate is often set by an appropriate SCFM flow meter. The minimum flow rate rated for the should be maintained when powered. MHI power controllers may be used to set the power and temperature.

Please click on the tabs below for more information

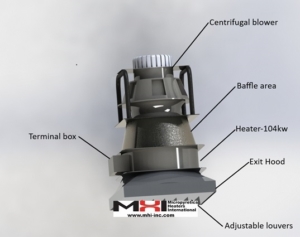

VTA750-4GS, VTA750-2GC, VTA900-10BL VTA-DPFVTA-DPF-6.5-1100 (DNA) (with Fan) VTA models include an integrated Type “K” thermocouple. The VTA models are highly energy-efficient, allowing for less energy use and cost savings. VTA models are fully compatible with MHI electronic control panels, allowing for accurate control of flow rates and temperatures for your process. Suggested uses for these models include integration into existing heating systems for cable conveyors, drying, process heating, coatings, production line heat treating, and several other specific process applications. Most units are compatible with an optional control panel. Contact us or call us at 513-772-0404. VTA-BL models have integrated air/gas controls. VTA models offer low flow cut-off with an extendable user interface. Fan control is available with the FANCS, which also includes a temperature controller. Schematic of Blower, Air Flow Valves, and Low Flow Safety Features are provided by MHI are shown in the adjacent picture. | 10kW power Airtorch VTA900-10BL – Use up to 900°C Designed for Energy Efficient Fan/Blower Inlet MHI Airtorch® Systems are offered with variable input attachments that suit customer requirements. The blower, valve, and low flow attachments are offered for the VTA900-10BL |

| Model | Power | Voltage | Max Temp | Max CFM @ Max Temp | Diameter> | Height | Air Supply | Inlet Integrated with Fan or Inlet Accepts Blower | Exit |

| All dimensions and accessory models are typical only. | AIR CONNECTION | ||||||||

| VTA750-4GS | 4kW | 208/220/230/240 | Call | Call | 4.0″ (100 mm) | 27.5″ (698.5 mm) | Fan model: MK4XL | Fan/Blower | 2″ NPT |

| VTA900-10BL | 10kW | 208/220/230/240 | 900°C | Call | 7.0″ (177.8 mm) | 27.5″ (698.5 mm) | Call | Blower/Please confirm with MHI the inlet and outlet dimensions of your specific unit | call |

| 3-Phase Custom | (high kW) | 240/440/480 | Variable: 700 -1100°C | Call/Contact | Call/Contact | Depends on Model | Typical 10-20 inches diameter and about 50″ Length. | ||

| ** : FANCS: Fan speed controller and temperature indicator | |||||||||

| Temperature | Lower Power (1-12 kW) | High Power (36-400 kW) |

| 600-900°C (now select VTA and LTA up to 1100C) | LTA, VTA, MTA925 | MVTA-750- Models |

| 750-900°C | (Custom) | MVTA-900- Models |

| 900-12000°C | DPF Models,, ZTA or MVTA-DPF models | (Custom) |

| High Pressure Enclosures | Up to 1200°C | Up to 1200°C |

| Resources |