Your MHI Inc. blog for saving energy and conserving water.

The global warming problem can be solved by not using fossil fuels and using electric heating instead. MHI offers many convective heaters, steam products, and radiative heaters. The capital returns today when converting from carbon-containing fuel equipment to electric heaters is attractive.

Examples of Energy and Cost Savings with an Airtorch.

Decarbonization and Sustainability principles

Examples of Airtorch use (case studies)

Examples of water and energy savings with the MightySteam

Examples of MightySteam Applications

All MHI Product Categories

Testimonials by Category:

- MHI practices and advances innovation in its technical fields and business methods.

- MHI uses and delivers only high-quality energy. MHI’s mission relates to high-quality energy preservation.

- A Leader in energy efficiency with materials design, integration, and innovation. We are integrating Engineering and Science Inventions.

- With an unsurpassed technology portfolio focused on Airtorch®, Radiative-products, and MightySteam® technologies.

- MHI ships small KW to MW devices all over the world.

- Committed to saving water in various industrial applications, an innovator in nano-texture development and surface engineering. It’s Quasi-R®

- Significant IP for products including energy materials, steam antimicrobials, and nanomaterials. Responsible use.

- Smart Power focused. Easy use and built-in scalability modularity.

- Clean energy manufacturer. Steam applications for antimicrobial. Airtorch® applications for CO2 conversion

- A Leader in Saving the Quality of Energy. MHI uses the most efficient electric control systems.

- MHI Inc. is a Leader in Advanced Manufacturing and Materials.

- A global presence for your innovative efforts.

- Scholarly References

- Mission

- MHI Web Store

Steam Pages:

https://mhi-inc.com/oab-instant-high-temperature-steam-models/

Air Heating/Process gas Heating

https://mhi-inc.com/electric-airtorch-process-gas-heaters/

Main Page for Heating Elements and Molybdenum di-Silicide Heaters

https://mhi-inc.com/high-temperature-heating-elements-mosi2-sic-gaxp-igmp-plasma-and-steam-ceramics/

Main Page for GAXP® Elements

Main Page for Silicon Carbide Heaters: https://mhi-inc.com/silicon-carbide-heating-elements/

Main Page for Microheaters/Fiber-heaters/Microtube Heaters

https://mhi-inc.com/microheaters-fibheats-and-holders/

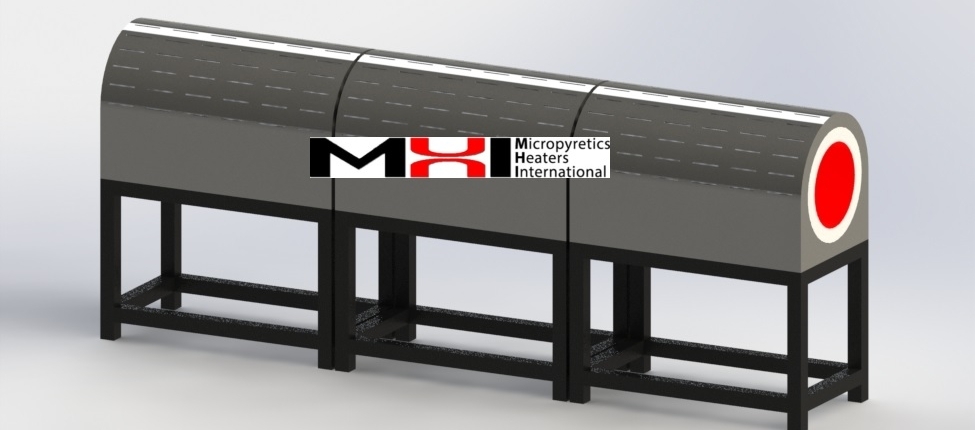

Main Page for Furnaces

https://mhi-inc.com/high-temperature-furnace-products-energy-efficient/

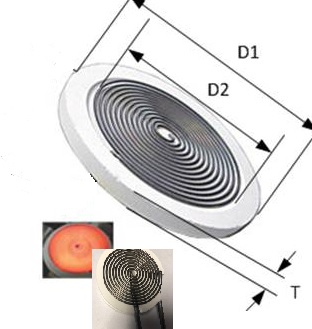

Main Page for Hot-Plates/Thermoplates™

https://mhi-inc.com/hot-plates-glow-radiators/

MHI Market

How many lbs. of CO2 do you avoid when converting to electric heating?

For every 1 kWh of energy made or converted by electric methods instead of by burning carbon-containing fuel, one prevents the production of between 0.6-2lbs of CO2 can be prevented, depending on the type of combustible fuel replaced. Some combustible fuels contain carbon only (like coal), and some have carbon and hydrogen (like natural gas). Source: https://www.eia.gov/. This calculation does not include any greenhouse gases other than CO2. Some NOx and unburnt methane could also be emitted with very high CO2eq when combusting natural gas.

Gases like methane are also very problematic climate gases (Source).

Improve Everything

- Energy Efficiency

- Sustainability

- Environment and Climate

- Water Savings

- Antimicrobial Steam Products

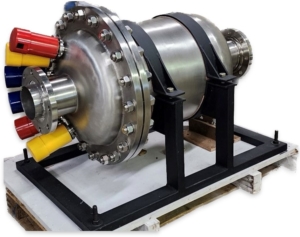

- Large Steam Generators

- MQL

- Reduce Plastics

- Recycle

- NeverDown™ Productivity

- Reduced Human Load

- Clean with Advanced MHI Technologies

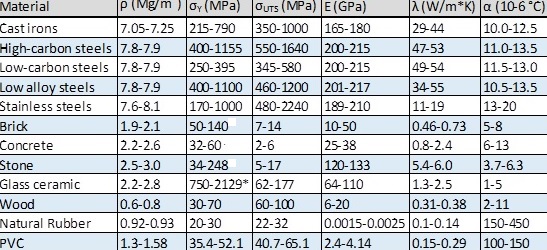

- Trivia for Materials and Thermal

- Trivia for Commercial Steam Generators

Why and how are MHI devices built with high energy efficiency? The use of high-grade energy almost automatically leads to many types of improved efficiencies including the use of much lower energy for a defined objective and much lower time of processing i.e. to higher productivity. MHI excels in high-grade energy conversion in the hot-products sector. High-temperature energy is high-grade energy. Now Quasi-R™ MHI technology further extends the dramatic energy savings up to the Exa-Joule range. The world uses ~450EJ or so today. Did you know that Energy requirements will increase by 1/3 over the next 20 years? The push will be to have high-quality energy.

Efficiency to preserve the quality of energy is important. MHI is working hard to reduce the amount of energy for any objective. This is the only way to reduce emissions. Did you know? human evolution is most likely related to energy efficiency – of digestion!

Simplicity is fully extended to the industrial sectors. This design philosophy is helping with MHI Inc.’s Climate and Sustainability Products.

From textured surfaces that use very little grease to reducing greenhouse gases – some examples of new technologies and SmartMachines are discussed below for Heating, Communication, Fiber-Forming, Furnaces, Fuel Production, Clean Reactions, Ultra-low friction, and many more…..

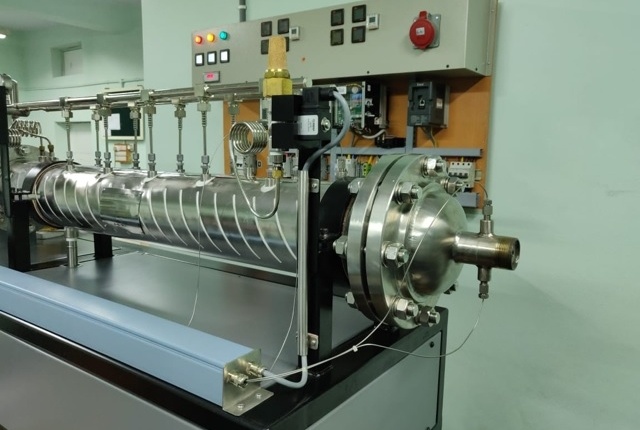

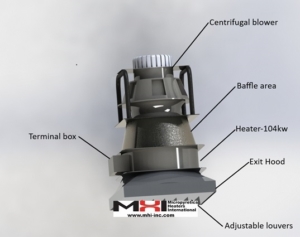

Even the very high power models are simply installed and used for Process gas heaters.

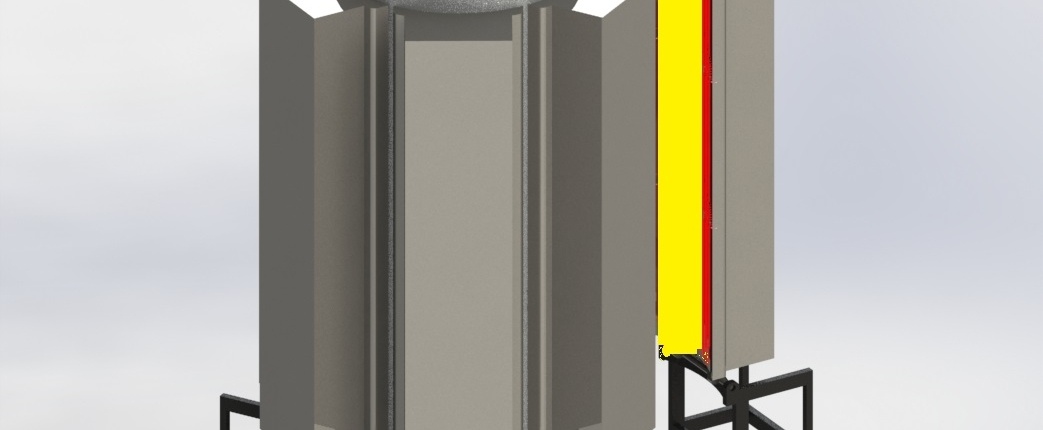

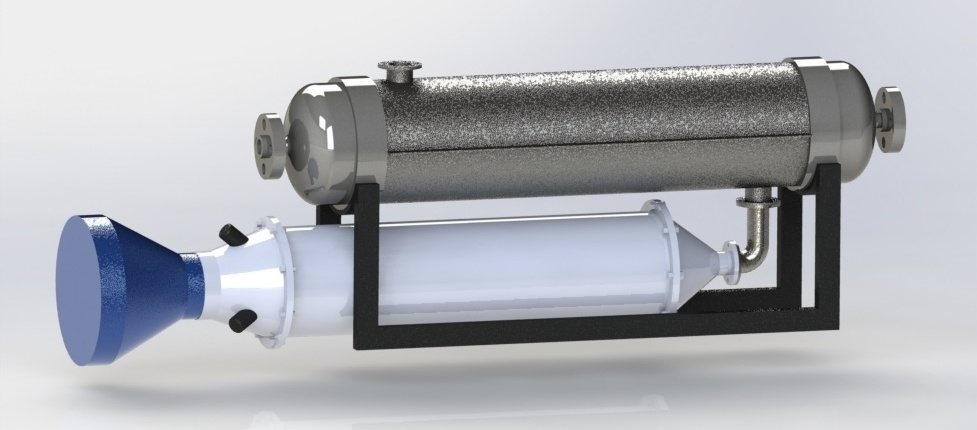

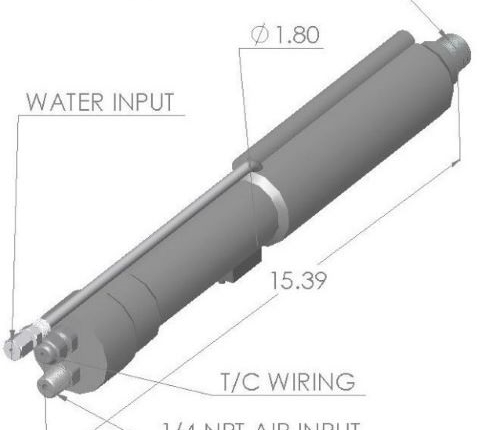

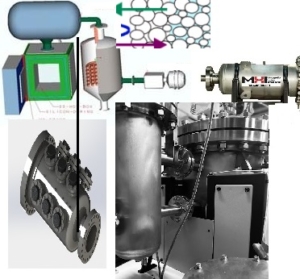

Process Air/Gas Heaters

Microheater® – now used by over hundreds of users for reducing footprint.

Heating Elements

|

|

|

The GiantHeater Revolution with GAXP for controlled large flow critical chemicals and other liquids.

High-Temperature Steam for Pharma Use

The Economics of high-quality thermal-devices

The best way to increase savings and reduce emissions is to lower the power consumption and total energy use for any objective.

Lower the device power usage by just 1 kW – Save $876 per year @US 10c/KWhr (A typical US household uses 2-4 KW (power) devices at home). Multiply this power by the hours used for obtaining the energy used and price-paid.

Industrial use of power is much higher ~ 100-1000 KW are used for industrial devices, especially when radiative, steam, and materials processing requirements.

MHI SmartPower devices offer substantial power savings. Click on this page for an overview.

How much do the devices cost, and how to find the best price?

How much detail should I use to specify my device?

The best price is obtained when you purchase the closest standard equipment for your desired use.

So it is best to specify the essentials.

For Steam: Choose the power, temperature, and kg/hr water usage. Examples of how to increase productivity? Drying, Antimicrobial, and Fuel Production. Waste to Fuel Production.

For Process Air Devices: Chose power and temperature. If in-line use, specify the pressure. What are MHI intelligent devices? Go Green with brilliant reactions enabled by hot clean gases. Heat all gasses, whether non-combustible or combustible,

For Furnaces: Choose the Temperature and power (based on the load). Choose furnace makers that provide at least a one-year warranty on the heating elements. How do distortion-free stainless steel enclosures improve life and efficiency?

For Heating Elements: Please review economics on this page. What is GAXP?

Items to Include

These items are now essential in a new device specification. They are best practices and should be part of your project when specifying a device.

- Warranty – Ask for a Warranty on the Heating-Element for a Steam Generator, Hot Plate, Airtorch, or Furnace.

- Ask for Testimonials – Or look for them on the manufacturer’s website.

- Does the manufacturer provide several levels of tutorials – Online forms?

- Online RFQs – Does the manufacturer provide this?

- Prices: Although not always comprehensive, there should be an online web store with price guidance.

- Does the manufacturer talk up energy efficiency and sustainability? It’s a good practice to ask the sales agent.

- Does the manufacturer believe in Simplicity of design?

What makes a device cost more?

Here is a list of items that typically may lead to an increase in the capital cost of a device.

- Short Time-Frame – The faster you need it, the more people will need to work on your order to make the deadline. More people equals more money.

- Customization– Customization could be great but is costly. Please be aware that the more items are built from scratch, the higher the cost.

- Spreading out payments: Paperwork from your end could take time – sometimes even compared to the build-out. Manufacturers routinely depend on being paid on time. The best prices are given when prepayment is made.

- Integration to 3rd Party Tools: Choose a manufacturer that provides its data acquisition system. The third part, tools can cost money and time to integrate.

Will I get my money back? What is my ROI?

When choosing a product, ask for typical Return On Investment Calculations if you will use it to generate revenue.

More:

- Check for Testimonials and Reviews. A good manufacturer will always post these.

- Is the repair policy sound, affordable and valuable? Machines will break down – maintenance is typically 10% of the initial purchase. The buyer should check if the manufacturer offers a comprehensive policy like the NeverDown(TM) guidelines.

- It does not hurt if the company you are dealing with has at least two decades in existence with continuous testimonials.

- Did the manufacturer or seller provide the quote promptly? If not, it could be a symptom of downstream delays. There are exceptions, but buyer beware.

Summary: There is no one answer to how to choose your best thermal device. The above are some guidelines that refer to good practices. Now include some Green Practices and obtain more benefits-

Some Benefits Of Going Green and even Blue In Manufacturing?

Attracting buyers as a way to do more business is a benefit of sustainability. How can MHI help? MHI technologies offer the potential to:

Reduce Costs

Energy use reduction can substantially reduce long-term electrical costs. Reducing water usage and cutting down on material-waste disposal can also add significant savings.

Enhance Brand Image

Establishing your company as a voice for environmental responsibility can lift the perception of your company and play a vital role in the success of your business overall.

Attract Committed Employees

One of the best ways to appeal to the next generation of workers is to demonstrate a commitment to the environment.

The smallest Microheaters made by MHI are the four below.

- The spiral https://mhi-inc.com/product/gaxp-1-spiral-microheater-for-vertical-use/

- The linear microheater https://mhi-inc.com/product/s12-200-1500-microheater/

- https://mhi-inc.com/product/gen2-heatpad%c2%99-with-1-diameter-hot-zone/

- Microtube. https://mhi-inc.com/product/microtube-gaxp-heat-12mm/

|  |  |  |

Steam- the new insta-steam revolution.

Applications of Steam Generators: From Drying Antimicrobial and Waste to Energy – Steam has many advantages e.g. reducing the amount of landfill dumping, reducing the amount of greenhouse-gas emissions and pollution, as well as reducing dependence on non-renewable fossil fuels.

OAB® Superheated Steam Generators 1300°C High-enthalpy Steam |  OAB® Superheated Steam Generators 1300°C High-enthalpy Steam |  HGA-M Models High Throughput On-demand |

Energy Savings: Why Should We Be Concerned With the Quality of Energy Conservation?

How much energy does the world use?

For a quick review of thermodynamics- https://mhi-inc.com/Converter/watt_calculator.htm and learn about the many temperature and energy scales!

For a nifty US, Government calculator, click here.

The weight of carbon dioxide per One Million BTU (293 KWhr) of burn with different fuels and processes.

The approximate price of this small amount of energy is US$30. A typical US home’s monthly electric bill is also in this order. Note for comparison that the average human exhales about~ 1 kg of carbon dioxide on an average day (about 7-9 kg a week) because human activity averages at about ~100 Watts or 341 BTU/hr of power usage (energy burn rate) .e. ~ about 200-250 lbs./ Million BTU.

An average size tree can absorb 20-25 kg of carbon dioxide per year and can sequester 1000 kg of carbon dioxide by the time it reaches 40 years old. At standard pressure and 15°C (59 °F), the density of carbon dioxide gas is 1.87 kg/m3 (0.1167 lb./ft3). Therefore, for a zero-sum, one roughly needs about 8-10 active trees per human. It is estimated that there are 3.04 trillion trees in the world of about 7.7 billion people (source: greenfuture.io/nature/how-many-trees-are-in-the-world). (Please note that these are all approximate numbers and should only be used for an order of magnitude analysis). Other living species also produce CO2 and CH4 as well – do the combustion processes listed below. The estimate for animal species is itself from 8-30 Million species. Each species may comprise large numbers in them. One pound (~454 grams) of carbon dioxide gas occupies 0.2426 m3 (8.566 ft3, 64 US gallons, 243 liters). Now compare emissions from energy usage that produce CO2. Use the Airtorch®, MightySteam®, or E-Ion for zero carbon emission.

Weight of carbon dioxide in lbs. per one million BTU of energy.

Diesel fuel /heating oil, 161.3 lbs

Gasoline, 157.2 lbs

Propane, 139.0lbs

Natural gas, 117.0 lbs

Aluminum Al 660°C 1220°F

Copper Cu 1083°C 1981°F

Gold Au 1063°C 1945°F

Iron Fe 1539°C 2802°F

Lead Pb 327°C 621°F

Nickel Ni 1455°C 2651°F

Palladium Pd 1555°C 2831°F

Platinum Pt 1773°C 3224°F

Silver, Fine Ag 961°C 1761°F

Tungsten W 3422°C 6197°F

Tin Sn 232°C 450°F

Zinc Zn 419°C 786°F

| Energy Conversion | kJ mol-1 | kcal mol-1 | eV | cm-1 |

| kJ mol-1 | 1 | 0.23901 | 1.0364×10-2 | 83.59 |

| kcal mol-1 | 4.184 | 1 | 4.3363×10-2 | 349.75 |

| eV | 96.485 | 23.061 | 1 | 8065.5 |

| cm-1 | 1.1963×10-2 | 2.8591×10-3 | 1.2398×10-4 | 1 |

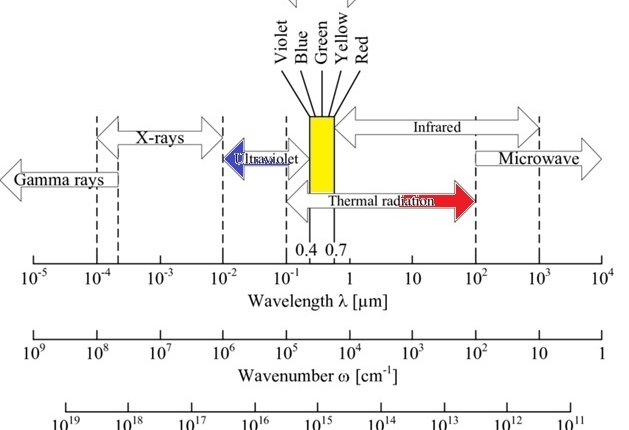

wavenumber wavelength and frequency chart

| Universal Constant | Units and Value |

| h (Planck’s constant) | 6.626075 *10-34 J s |

| kB (Boltzman’s constant) | 1.38065 *10-23 J K-1 |

| NA (Avogadro’s number) | 6.022136 *1023 mol-1 |

| c (speed of light) | 2.9979245 *108 m s-1 |

| ao (Bohr radius) | 5.2917724 *10-11 m |

| e (charge of an electron) | 1.6021773 *10-19 Coulomb |

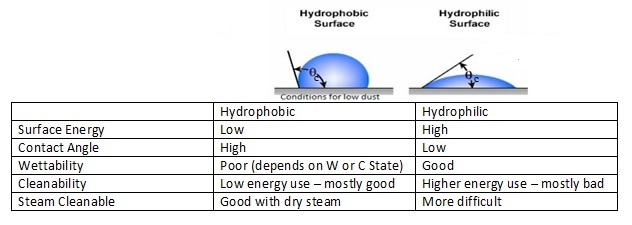

Surface Energy = Joule/m2= Newton×m/m2= Newton/m= Force/Length = Surface Tension

Metals typically 1000 mJ/m2

Ceramics typically 500 mJ/m2

Glass typically 100 mJ/m2

Soft Matter/Plastics typically 50 mJ/m2

| Material | Volumetric heat capacity, [MJ/(m3 °C)] | |

|---|---|---|

| Dry | Saturated WITH WATER | |

| Clay | 1.5–1.6 | 1.6–3.4 |

| Silt | 1.5–1.6 | 1.6–3.4 |

| Sand | 1.3–1.6 | 2.2–2.9 |

| Gravel | 1.4–1.6 | 2.4 |

| Peat | 0.5–3.8 | |

| Claystone/Siltstone | 2.1–2.4 | |

| Sandstone | 1.6–2.8 | |

| Quartzite | 2.1–2.2 | |

| Marl | 2.2–2.3 | |

| Limestone | 2.1–2.4 | |

| Micaschists | 2.2 | |

| Quartzite | 2.1 | |

| Marble | 2.0 | |

| Peridotite | 2.7 | |

| Granite | 2.1–3.0 | |

| Gabbro | 2.6 | |

| Diorite | 2.9 | |

| Basalt | 2.3–2.6 | |

| Concrete | 1.8–2.0 | |

| Steel | 3.12 | |

| Water | 4.186 | |

| Air | 0.0012 | |

Decibels measure the sound intensity (Amplitude)

Sound is energy that travels in pressure transverse waves. It can be measured in two ways: frequency and amplitude.

- Frequency, reported in Hertz (Hz), measures the number of sound vibrations in one second. This corresponds to how low- or high-pitched a sound is. A child’s voice is high-frequency, for example. Health-wise, many older adults develop what’s known as high-frequency hearing loss, making it harder to hear sounds that are higher pitched.

- Amplitude reported on the decibel (dB) scale measures sound pressure or forcefulness. This is the sound “volume.” The more amplitude a sound has, the louder the volume.

- High Amplitude and High Frequency are a bad combination for the ear. See the chart below for safe to dangerous dB (not all sounds in the chart below are at the same frequency).

- What Is the difference between dB and dBA? dB sound pressure levels are unweighted. dBA levels are “A” weighted according to the weighting curves to approximate the way the human ear hears. The conversion is not simple and is specific to the ear and recording; a 100 dB level at 100 Hz could be perceived to have a loudness equal to only 80 dB at 1000 Hz. Humans can hear about 20 Hz to 20 kHz.

dB Scale

10 dB is regular breathing – bottom of green

100 dB is a Car Horn – top of yellow

150 dB- Loud firecrackers – top of red

MHI Inc. USA

MHI Inc. USA